Geothermal Recharge Equipment

Contact Us

Contact Us

产品详细

Geothermal recharge equipment

1. Equipment Overview:

Geothermal recharge is a measure to avoid thermal pollution and chemical pollution caused by the direct discharge of geothermal wastewater, and plays an important role in maintaining the pressure of thermal storage and ensuring the technical conditions of mining in geothermal fields. Geothermal recharge is a powerful measure to realize the sustainable development of geothermal resources. It has been widely used in various countries around the world. It is of great significance for the protection of geothermal resources, reducing waste of resources, extending the life of production wells and reducing environmental pollution. The geothermal water of the geothermal water recharge equipment enters the cyclone sand remover for sand purification, and the rest is filtered into the heating pipe network. The used tail water enters the geothermal hot water recharging equipment, and the geothermal tail water undergoes coarse filtration and fine filtration water treatment to recharge the geothermal water to the ground in the same layer to recycle the geothermal resources.

2. Components:

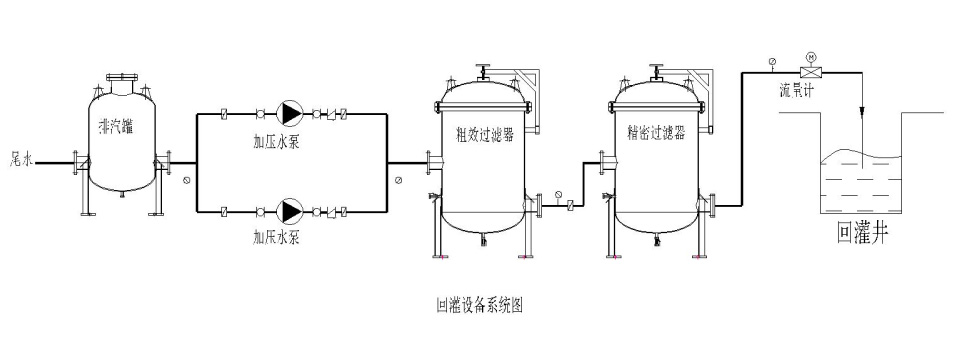

Geothermal water recharge equipment is mainly composed of: coarse effect filter, precision filter, exhaust tank, pressurized water pump, recharge well and other parts.

3. Principle characteristics:

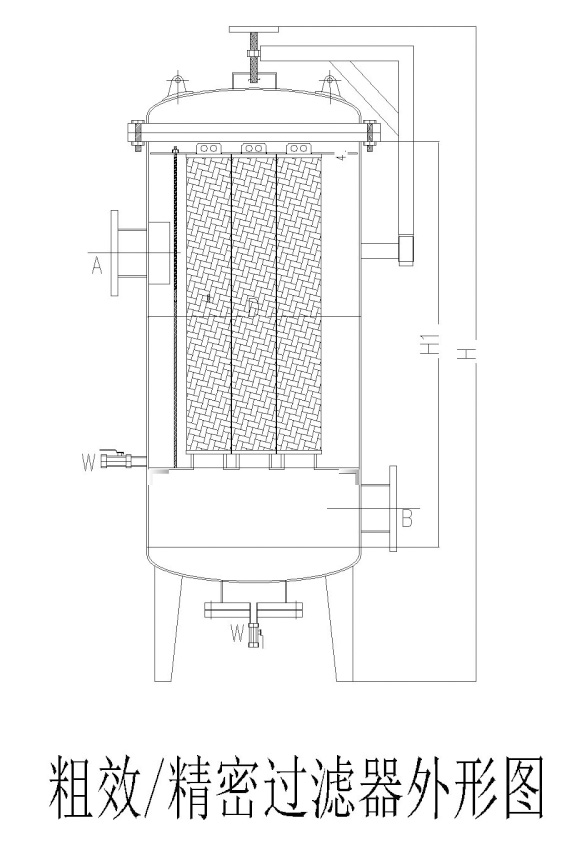

The coarse effect filter and precision filter produced by our company are honeycomb tubular filter elements. It is suitable for the further purification of water with low suspended matter or low mechanical impurities. The honeycomb tubular filter element uses its special process to form an outer and inner dense honeycomb structure, which has excellent filtering characteristics. The solid-liquid phase separation process of the treated water is completed to achieve a satisfactory water production effect. However, as the water production cycle increases, the filter element will be subject to contamination due to contamination, and its operating resistance will increase accordingly. When the pressure difference between the inlet and outlet of the equipment is higher than the initial pressure difference by 0.15Mpa, the filter element should be replaced in time.

In addition, our company's geothermal well refilling equipment can also be equipped with backwashing function, which can choose differential backwashing or time-type automatic backwashing according to specific conditions, reducing unnecessary investment in manual cleaning.

4. Structure

This equipment is a cylindrical steel structure with elliptical heads on the top and bottom. A porous plate with filter elements inside the body divides the column into two parts: filtering and water outlet. The filter element is a carbon steel separator of equal cylinder thickness. The filter element is made of PP cotton or stainless steel, which has a certain heat resistance. Filtration accuracy is 100μm, 50μm, 30μm, 10μm, 5μm, 1μm, and different levels of filtration can be achieved according to water quality. The small device can be made of stainless steel, and the cylinder is equipped with swing arms, which is convenient for later maintenance.

5. Performance characteristics

(1) High filtration accuracy and uniform filter pore diameter.

(2) The filtration resistance is small, the flux is large, the pollution interception ability is strong, and the service life is long.

(3) The filter core material has high cleanliness and no pollution to the filter medium.

(4) Resistant to chemical solvents such as acid and alkali.

(5) High strength and high temperature resistance, the filter element is not easy to deform.

(6) Low price, low operating cost, easy to clean, and replaceable filter element.

(7) Equipped with a booster pump to deal with recharge wells with insufficient water swallowing capacity and meet recharge requirements.

Geothermal tail water treatment and recharge equipment eliminates the uncontrolled waste of geothermal water and environmental pollution to the greatest extent, making geothermal water a truly recyclable clean energy. With the continuous development of China's economy, people's awareness of environmental protection has been continuously strengthened. China's geothermal water tailwater treatment technology continues to develop, and recharge technology will become more mature.

Recharge equipment parameter table

|

Serial number |

Treated water |

Inlet pressure |

Coarse effect / precision filter |

Exhaust tank |

||||||||

|

Filtration accuracy |

Number of filter elements |

Connection size |

Diameter |

Height |

Sewage outlet |

Connection size |

Diameter |

Height |

Sewage outlet |

|||

|

1 |

30-40 |

≥0.3 |

50/5 |

2 |

DN100 |

400 |

2000 |

DN25 |

DN100 |

400 |

1400 |

DN32 |

|

2 |

50-70 |

≥0.3 |

50/5 |

3 |

DN100 |

500 |

2000 |

DN25 |

DN100 |

400 |

1400 |

DN32 |

|

3 |

70-90 |

≥0.3 |

50/5 |

4 |

DN125 |

600 |

2100 |

DN32 |

DN125 |

500 |

1450 |

DN40 |

|

4 |

100-120 |

≥0.3 |

50/5 |

5 |

DN150 |

700 |

2150 |

DN32 |

DN150 |

600 |

1500 |

DN40 |

Recharge equipment related drawings

6. Recharge water requirements

1. Recharge at the same level

The recharge target layer is basically the same as the geothermal exploitation heat reservoir. The recharge water source should be the tail water that enters the recharge well through the closed system after heating.

2. Different layer recharge

When recharging in different layers, the water quality of the production layer and that of the thermal reservoir of the recharge well are basically the same, the salinity is similar, and the water quality of the production well is better than that of the recharge well. At the same time, the compatibility test of the two kinds of water quality should be carried out before the recharge, and the water quality of the recharge water source should be evaluated. It can be recharged under the premise that the recharged thermal reservoir is not affected by recharge water, otherwise it should not be recharged.

3. Water quality evaluation of recharge water source

The evaluation method and judgment standard of the water quality of the recharge water source shall be implemented in accordance with GB / T 11615-2010. The requirements of the recharge water source shall refer to the main control indicators recommended by the geothermal recharge water.

7. Preparation before operation

1. Principles of Operation

(1) After the geothermal heating, the tail water is filtered and exhausted, and then used natural recharge or pressurized recharge to the recharge well. For the schematic diagram of the process, see the system diagram of the recharge equipment.

(2) The operator should be familiar with the geothermal water recharge system and master the operation essentials of various equipment before taking up the post.

(3) Check the system carefully before operation; the wellhead device, filter device, etc. should be tested to see if the equipment is in good condition and is operating normally.

2. Check the recharge system

(1) Electrical instruments

Before the recharge operation, electrical instruments should be strictly checked to ensure that the power supply in the recharge system is safe and in good condition, and various instruments and instruments are operating normally.

(2) Recharge pipe network

Extract the ground hot water from the mining well through the recharge pipe network to the bypass outlet to check whether the recharge pipe network is smooth; close the valves at both ends to inject water into the recharge pipe network to check whether the pipe network is leaking or leaking.

(3) Purification (filtration) treatment system of recharge water source

Check whether the sewage pipe is unobstructed; when there is recharge water in the filter device, whether there is a pressure difference between the inlet and the outlet. When the pressure difference reaches 50kPa ~ 60kPa, the filter material should be replaced or cleaned in time to ensure the smoothness of the filtration system.

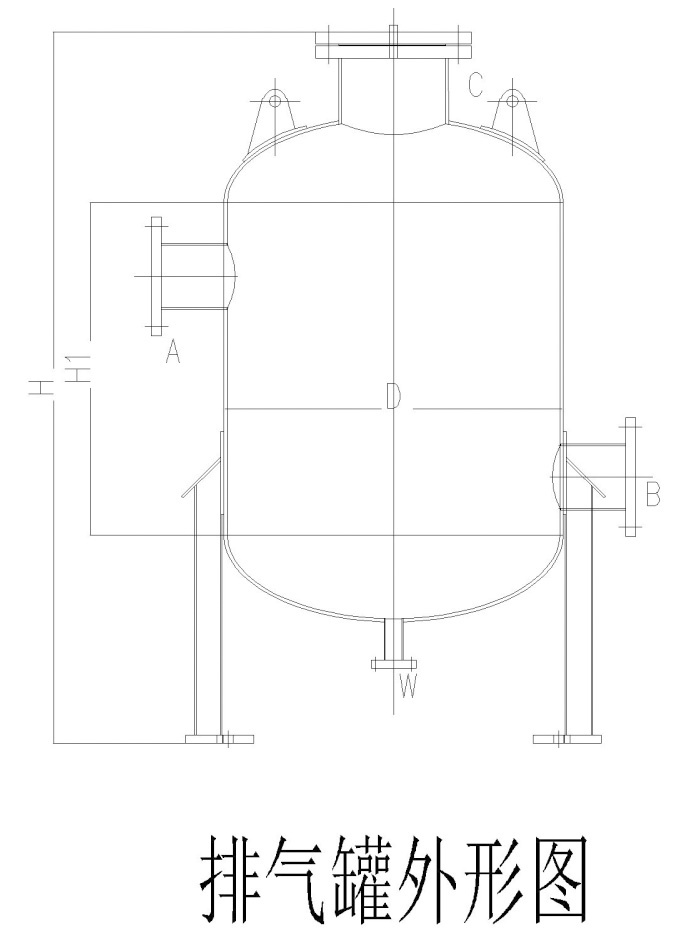

(4) Exhaust tank

Check whether the sewage pipe is smooth; when there is recharge water, close the valve behind the exhaust tank to check whether the automatic air release valve is exhausted normally.

(5) Nitrogen protection device

Check whether the gas pipeline of the nitrogen protection device is smooth or leaking, and the pressure of the nitrogen filling bottle should be greater than atmospheric pressure.

(6) Pressure recharge device

When using pressure recharge, check whether the pressure centrifugal pump is operating normally, and at the same time add a gas release valve on the well pipe of the recharge well.

(7) Pull back system

Before lifting, check whether the submersible pump is installed correctly, whether the lifting drainage system is smooth, and whether the depth of the pump is appropriate.

3. Pipeline flushing

Before the recharge production operation, the entire system pipeline is thoroughly rinsed, including the recharge well pipeline and water delivery network. The rinsing time depends on the cleanliness of the tail water, and it can be refilled until the water is clear of impurities.

8. Recharge operation

1. Basic requirements

(1) When the recharge operation is running, the water level of the recharge pipe should be always below the level of the recharge well.

(2) Closely monitor the data changes of water level, recharge volume, filter device, pipeline pressure and other data in the recharge well, correctly determine whether the system has a blockage and other conditions that affect the recharge effect, and take effective measures to prevent and control in time.

(3) Ensure that the wellhead monitoring system (remote or dedicated manual monitoring instruments) of the recharge well is normal, the observed data is objective, true and correct, especially the accuracy of the manually monitored flow meter and the smoothness of the water level measuring tube If the instrument is damaged, it should be replaced and repaired in time.

2. Natural recharge operation

(1) Before the recharge starts, the dynamic start data of the recharge system should be monitored.

(2) Adjust each valve to the recharge mode to allow the recharge water source to be injected into the recharge well from the recharge water pipe.

(3) Determine the basic recharge amount based on the recharge test or the previous year's recharge amount data.

(4) Use the control valve to adjust the recharge volume. The recharge volume should be 20 m3 / h, 30 m3 / h, 40m3 / h ... increase gradually from small to large, all the way to the basic recharge volume.

(5) Observe the value of the pipeline pressure gauge closely to confirm that the recharge system is unobstructed, and when the water level in the recharge well rises without rapid and obvious changes, the recharge volume is stabilized and the recharge is operating normally.

(6) When the water level of the recharge well rises fast, pay attention to encryption monitoring. When the water level rise is less than 5m from the wellhead, stop the recharge and promptly raise.

(7) Record observation data regularly as required to ensure accurate and complete data recording.

(8) After the recharge is basically stable (generally after 2 hours of normal operation of the recharge), take a sample and refer to SL 187 at the wellhead of the recharge well.

3. Pressure recharge operation

(1) Before the recharge starts, the dynamic start data of the recharge system should be monitored.

(2) Adjust each valve to the recharge mode to allow the recharge water source to be injected into the recharge well from the recharge water pipe.

(3) Determine the basic recharge amount based on the recharge test or the previous year's recharge amount data.

(4) Use the control valve to adjust the recharge volume, the recharge volume should be 15 m3 / h, 20 m3 / h, 25 m3 / h, 30m3 / h ... increase gradually from small to large After the valve overflows, close the air release valve again and adjust the recharge volume to the basic recharge volume.

(5) Closely observe the value of the pipeline pressure gauge to confirm that the recharge system is unobstructed, and that there is no rapid and obvious change in the pressure in the recharge well, stabilize the recharge volume and recharge normal operation.

(6) First use the pressure of the submersible pump of the mining well to carry out pressure recharging. When the pressure is insufficient, turn on the centrifugal pump to pressurize the recharging.

(7) The recharge system should meet the design pressure requirements, and the maximum pressure should be less than the design pressure value of the recharge system to ensure the safe operation of the system.

(8) The pressurized centrifugal pump should not cut off the water and empty the pump, and the pressure will gradually increase from small to large.

(9) Record observation data regularly as required to ensure accurate and complete data recording.

(10) After the recharge is basically stable (after the water level reaches the wellhead and the pressure tends to stabilize), take a sample at the wellhead of the recharge well and send it for inspection.

4. Recharge well operation

(1) Pore-type thermal storage recharge well back up

1) Lifting facilities: select the appropriate submersible pump according to the maximum water volume in the pumping test of the recharging well, and a special water level measuring tube should be welded on the side of the pump tube. The depth of the submersible pump is determined with reference to the maximum depth of the pumping test.

2) Submersible pumps and pump tubes should be treated with anti-corrosion and anti-scale to ensure no rust and corrosion, and the test tube is unobstructed.

3) Pore-type thermal reservoirs need to be pumped back due to the problem of decay of irrigation volume during the recharge process, and recharge operation with pumps should be carried out.

4) Before and after the recharge every year, the recharge well should be lifted.

(2) Bedrock thermal storage and recharge well recovery

Depending on the reduction of the unit's recharge volume in the recharge well, take back measures.

(3) Operation procedure

1) Record the initial value of each data according to the table content.

2) Set each valve to the return mode, and check whether the return drainage channel is smooth.

3) The well should be pumped and washed with the maximum amount of water until the sand content is less than 1 / 200,000 (volume ratio) or there is no obvious change in water temperature.

4) Record observation data and cleanliness of water quality regularly as required.

5) Before the end of the lift, take a sample at the wellhead of the recharge well to analyze the quality of the geothermal fluid.

9. Dynamic monitoring of recharge system

1. Water level, water volume, water temperature and pressure monitoring of recharge system

(1) Monitoring period

Water level monitoring is divided into recharge period and non-recharge period, water volume and water temperature monitoring is divided into recharge period and return period, and pressure monitoring of recharge system is recharge period.

(2) Monitoring frequency

1) During the non-recharging period, the water level meter will automatically monitor the monitoring, and the frequency is set to 1 time / 1 day, and the manual monitoring frequency should be 1 time / 10 days; / 30 minutes, manual monitoring frequency should be 1 time / day.

2) The monitoring frequency of water volume and temperature is the same as the monitoring frequency during the water level recharge, and the observation time is the same.

3) The pressure monitoring frequency of the recharge system should be set once every 30 minutes. If necessary, encryption monitoring should be performed to ensure the safety of the pressurized system.

(3) Content of monitoring data record

Fill in the form accurately and completely according to the actual observation data.

(4) Precautions for monitoring

1) The monitoring equipment should adopt automatic monitoring, use remote control system, and set warning value for water level and pressure.

2) Perform manual measurement before, during and after recharging, and check the monitoring equipment.

3) To maintain data continuity, once the monitoring instrument is damaged, it must be replaced in time.

2. Review of original monitoring data

(1) Original monitoring data

The original monitoring data includes water level, water volume, water temperature, pressure and other data.

(2) Content of original data review

The original data review includes:

a) Monitoring means, monitoring frequency and monitoring accuracy;

b) Whether the monitoring instrument is normal, whether the monitoring data is accurate, and the reason for the monitoring error;

c) Whether the monitoring content is complete in various monitoring projects and whether the monitoring table format meets the requirements;

d) Audit of monitoring abnormal points and monitoring interruptions, explain the reasons, and make remarks;

e) Monitoring data should be used to briefly evaluate the impact on the thermal reservoir after recharge.

10. System maintenance and maintenance after stopping irrigation

1. Recharge pipe network and recharge equipment protection

(1) Maintenance of refilling equipment: the filter device should remove the filter bag (net), rinse the tank with fresh water, drain it, close the inlet and outlet, and keep it properly after air-drying; the exhaust tank should be drained with fresh water, drain, air-dry and close Import and export, sealing treatment or nitrogen filling.

(2) Maintenance of the recharge pipe network: the recharge equipment closes the inlet and outlet, flushes the pipeline with fresh water, waits for the water to clear the sand and fill it with fresh water, closes the inlet and outlet, and performs sealing treatment.

2. Pump tube and well tube protection

After the irrigation is stopped and pumped up, the pump tube is proposed to remove stains, rust, etc. inside and outside the tube, and maintenance measures such as anti-corrosion and anti-rust are done. The storage site should be dry and ventilated; close the wellhead of the recharge well and use a nitrogen protection device to fill the well Nitrogen.

3. Testing of instruments

During the irrigation stop, the equipment and instruments of the recharge system should be tested according to the requirements to ensure the accuracy and reliability of the monitoring data.

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn