Heat Exchanger Equipment

Contact Us

Contact Us

产品详细

Plate heat exchanger

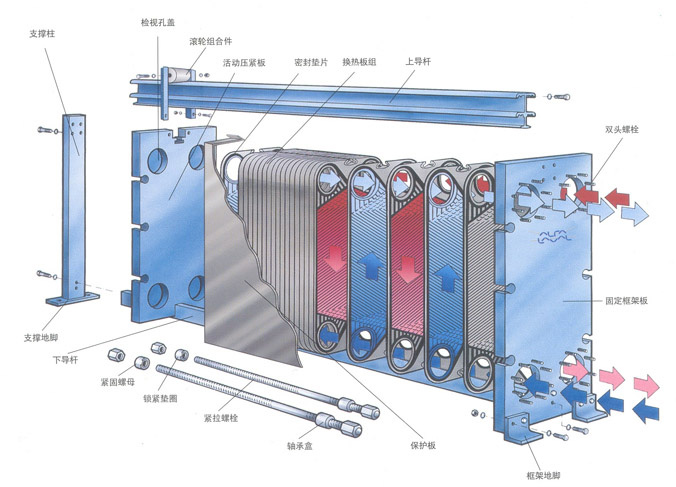

The basic structure and characteristics of the removable plate heat exchanger of Shandong Youxin HVAC Group Co., Ltd .: the removable plate heat exchanger is composed of plates, gaskets, clamping bolts, guide rods, brackets and other basic components. It is a heat conduction element, which determines the heat transfer rate, resistance loss, pressure resistance, applicable fluid and service life of the plate heat exchanger; the gasket determines the pressure resistance of the plate heat exchanger, and is suitable for the fluid and maintenance cycle. The plate heat exchanger adopted in this bid is a high-quality plate heat exchanger of Shandong Youxin Group. It comprehensively introduces the advanced technology of Alfa Valve Company in the aspects of plate design, mold manufacturing, sealing structure manufacturing, thermal engineering and hydraulic design. Fully taking into account the actual operating conditions of China's plate heat exchangers, so while having international advanced technology and quality, it is more suitable for the needs of national conditions.

Structure and dimensions:

For BR series products, the whole machine is equipped with two types: ordinary structure (used in infrequent disassembly and washing conditions) and hanging structure (used in more frequent disassembly and washing conditions).

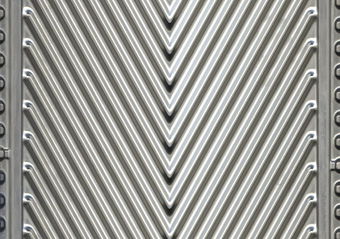

The common structure is composed of main parts such as herringbone corrugated sheet, sealing pad, pressing plate, upper and lower positioning bolts, pressing bolts and so on.

Suspension structure is composed of main parts such as herringbone corrugated sheet, sealing pad, fixed pressure plate, middle plate, movable pressure plate, bracket, upper and lower positioning beam, compression bolt and so on.

◆ Excellent tonnage, high precision, CNC hydraulic machine

Shandong Youxin Group adopts a hydraulic press (6000 tons) of excellent tonnage, high precision and numerical control (6000 tons) for one-time press forming and overall blanking process. During the pressing process, the film-coated soft processing technology is used to make the plate with high precision and good forming quality. No scratches and scratches on the surface of the film. The special hydraulic press for plates with excellent tonnage ensures the forming accuracy of the plates.

◆ Unique extended die processing technology

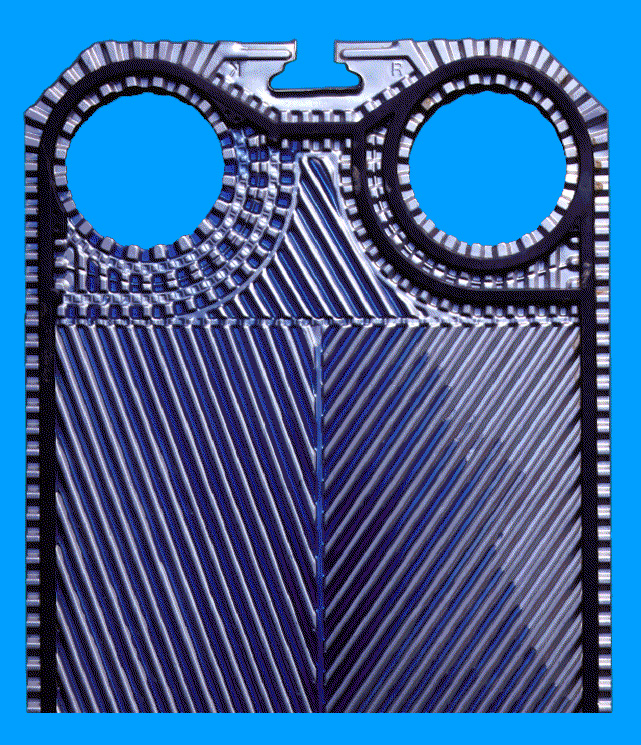

The manufacturing quality and durability of plate heat exchanger mainly come from the forming quality, processing precision and sealing structure type of the plate. The manufacturing quality and precision of the plates come from the mold. Shandong Youxin Group's high-quality series plate heat exchanger molds are designed with extended and closed molds. The outstanding advantages of the extended molds are the high precision of the mold, the shape of the plate and the shape of the mold are consistent, so that the tensile deformation of the plate is very small, and the thinning of the plate is very small It can realize the processing of very thin plates (the thinnest reaches 0.4mm). This mold requires high processing accuracy. Shandong Youxin Group has a CNC machining center, which is the earliest domestic CAD / CAM technology for processing molds, ensuring the design of the mold Precision and processing accuracy.

◆ Chocolate diversion area

Optimize the inlet and outlet flow distribution, eliminate dead angles, improve heat exchange efficiency, reduce shunt resistance, effectively avoid the accumulation of dirt, and set the isobaric line in the reverse flow area to make the water flow distribution more uniform.

◆ Non-adhesive gasket

No-stick bayonet gasket No glue assembly, no pollution, easy to clean and replace, unique signal hole design, to prevent cross-contamination of media, anti-slip groove design Adhesive-free gaskets are currently the most commonly used sealing gaskets in the world. The plate heat exchangers of Shandong Youxin Group use snap-on CLIP-ON gaskets. The high-quality gaskets produced by Parker, a Sino-US joint venture, use Manufactured from raw materials provided by manufacturers with outstanding reputation (Dubon Denmark \ Bell Germany), the gasket has good elasticity, low permanent deformation rate and long service life. And made great improvements on this basis. The gasket is embedded in the groove of the plate and fixed on the plate heat exchange plate through the gasket claws. It is not easy to fall during assembly, and no special tools are required during assembly. The gasket adopts a roof-type structure with good sealing performance and prolongs the service life. The plate heat exchanger assembled by the gasket can withstand a pressure of 40 Bar. The gasket is designed with many leak detection measures to prevent fluid mixing. When the gasket fails, it is immediately discovered and improved. At the same time, when the heat exchanger is shut down for maintenance, the gasket can be removed to clean the heat exchange fins, to avoid the expansion of the sealing tape or other solutions and affect the service life. No special tools are needed when reinstalling. carry out.

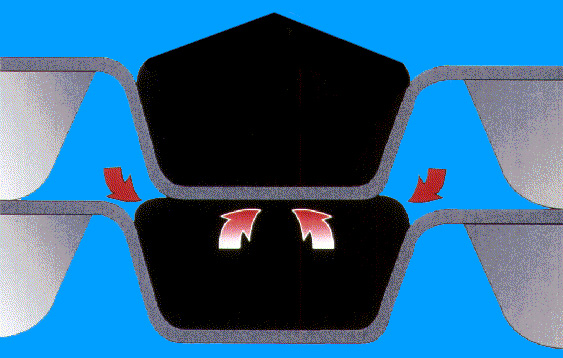

◆ Closed seal groove gasket

The gasket groove adopts a closed design, so that the gasket will not be exposed to the atmosphere during clamping, and the gasket has less contact with the outside air and internal media, which reduces the aging and corrosion of the gasket (see the following figure), thus achieving The plate heat exchanger operates safely and reliably for a long time.

◆ Five-point positioning suspension locking system

The plate adopts the suspension positioning system in the shape of dovetail groove. The system has three functions: suspension: suspending the plate on the upper guide bar so that it can slide freely back and forth along the upper guide bar; positioning: five-point positioning of the dovetail groove and the stepped flange design of the outer corner of the corner of the four corners of the upper and lower plates Accurate positioning on the left and right; Locking: The newly designed dovetail groove flange allows the plates to automatically lock with each other when clamped, thus ensuring that all plates can be accurately aligned under any installation conditions, avoiding human factors deviation. The four corner concave and convex grooves of the plate, the dovetail groove folding and the right-angle Z-shaped positioning technology are used to make the plates bite and lock each other during assembly, and will never be in position. The special design provides safe and reliable positioning during the fixing process, stable and neat plate arrangement, and the gasket is accurately sealed in the groove, which can prolong the service life of the gasket.

◆ New gasket design

The triangular roof design adopted by our company's plate heat exchanger sealing pad structure has better sealing effect, and the plates are disassembled and disassembled many times without deformation.

◆ Hard and soft board design

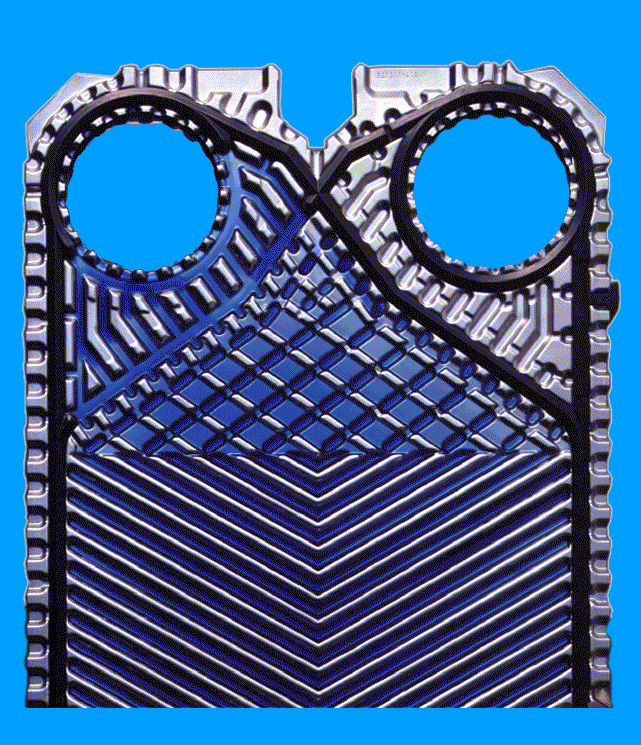

Our company's plate heat exchanger adopts advanced thermal mixing design method, which can achieve the heat exchange volume-flow-in a fairly wide range of parameters, allowing the pressure drop to be completely matched and saving heat exchange area.

◆ CNC machining center

Shandong Youxin Group strives for excellence in its products, and produces and manufactures strictly in accordance with the process reviewed by well-known process experts. It has invested heavily to introduce the industry's advanced CNC cutting center, CNC welding center, and CNC cutting center to ensure the product quality is fundamentally guaranteed

◆ Hydraulic film coating process

The plate heat exchanger produced by Shandong Youxin Group adopts the pre-coated hydraulic membrane process to ensure that the plate is not damaged during the cutting, pressing, punching and other processes.

◆ Excellent shape design

The in-depth development of products by Shandong Youxin Group has enriched the family of plate heat exchangers. The plates are designed with a variety of corrugation depths and angles. By combining different forms of plates, an ideal ideal for the working conditions is formed. Heat Exchanger. We have heat exchangers suitable for wide and narrow flow channels, which can be used for different working conditions and some special media. Plates of the same model can also be used in the form of H-plate or L-plate to achieve the most optimal design results and meet the long-term use effect. The plate adopts one-time forming technology to reduce the cumulative error and tremor caused by multiple stamping on the plate, and prolong the service life of the plate.

◆ Special clamping size scale

Shandong Youxin Group plate heat exchangers are equipped with special heat exchanger clamping size marks. Users can pre-tighten the plate heat exchangers to the size of the nameplate according to the scale requirements on the spot. At a glance, the plate heat exchanger can be easily installed as required.

◆ Advanced frame structure

The plate heat exchanger of Shandong Youxin Group adopts a single-side flow design. The plate heat exchanger plates can be rotated 180 ° C to become another channel plate, forming a heat exchange channel, and all plates are clamped between the plates The interlocking mechanism uses movable bearings to easily clamp the heat exchanger to the appropriate size, and all bolts are treated with high-strength galvanizing.

◆ Plate material and thickness

Shandong Youxin Group's plate heat exchangers are all made of imported stainless steel plates. All plates are 0.5-0.7mm thick. The service life is much longer than that of ordinary plate heat exchanger plates. Our strict requirements on materials and heat exchanger plates The unique design of the plate makes our plate can bear the pressure of 25Bar when the thickness is 0.5mm, the plate of 0.6mm can withstand 40Bar, and it can still operate normally when the fluid pressure difference on both sides of the plate heat exchanger is ≥16 kg. This is particularly important for the refrigeration industry. From the principle of mechanical strength, if a 0.4mm thick plate is used, the pressure resistance of the plate is greatly reduced. In severe cases, the plate will be misaligned and the fluid will leak. The hard particles in the fluid will have a high degree of friction with the plate At this time, the resistance to breakdown of its plates is greatly reduced.

● Compared with other heat exchangers, the plate heat exchanger is compact

● Rich plate types, multiple angles, multiple groove depths, and different combinations form an ideal heat exchanger that is most suitable for working conditions

● The plates are all formed at one time, and high-precision molds are used to reduce the physical force of the plates and improve the balance of the plates, greatly extending the service life of the plates

● Reasonable plate flow guide design, prevent plate scaling, improve heat transfer coefficient, up to 7500w / m2.k

● Plate positioning system, unilateral flow design and special clamping size mark, easy to install and take over, operation and maintenance

● Heat exchangers with different materials are available, such as plates made of stainless steel, titanium or other special alloys to meet the requirements of different industries

● The plate is easy to access and inspect, which is convenient for manual cleaning. In many occasions, it can be cleaned by the countercurrent flushing method. The daily cleaning does not need to spend too much time, and no special training is required.

● In the form of thermal mixing, by changing the flow method or increasing the number of flow channels, countless combinations can be achieved, from a single countercurrent flow method of two fluids to a multi-flow flow method of three or more fluids. The division provides more and more reasonable options to meet different process requirements

● Heat transfer and pressure drop can be adjusted, through the combination of plates in the adjustment of heat transfer coefficient and pressure drop, the best heat transfer coefficient is obtained, thereby reducing equipment investment

● Economical, because of its high heat transfer coefficient and easy installation and maintenance, the initial investment and operation and maintenance costs are greatly reduced

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn