Water Supply Equipment

Contact Us

Contact Us

产品详细

Condenser rubber ball cleaning device

The rubber ball cleaning device is a very important cleaning device in thermal power (nuclear) power plant equipment. In the heat exchange pipeline, any scale formed by the deposition of tiny impurities will reduce the heat exchange efficiency, causing an increase in the exhaust pressure of the steam turbine, and ultimately resulting in a loss of output energy of the generator set. Therefore, keeping the heat exchange pipeline of the condenser clean and improving the heat exchange efficiency of the condenser have a very important influence on improving the thermal efficiency of the entire unit.

The condenser rubber ball cleaning system is to make the elastic rubber ball with a wet diameter slightly larger than the inner diameter of the heat exchanger tube of the condenser pass through the heat exchanger tube of the condenser. In this process, the rubber ball scrubs the inner wall of the heat exchange tube, thereby cleaning The dirt and scale deposited on the inner wall of the water pipe can prevent the growth of microorganisms and prevent corrosion. Ensure that the inner wall of the heat exchange tube is clean, ensure a good heat exchange effect, and improve the thermal efficiency of the unit.

1. Purpose

1. Purpose

The rubber ball cleaning device can clean the condenser cooling tube without reducing the load of the unit, improve the heat transfer effect of the condenser, prevent the thermal efficiency of the steam turbine from decreasing due to the increase of back pressure, and prevent the cooling tube from corroding due to scaling and extending The service life of the cooling pipe is an ideal device for energy saving and improving working conditions.

2. System composition

The device is composed of a ball receiving net, a secondary filter, a ball loading chamber, a rubber ball delivery pump and an electrical control cabinet. For large units, a unit system is used, that is, each side of the condenser uses a ball receiving net, a ball loading chamber, and a rubber ball delivery pump; for small units, a common system is usually used, that is, the ball loading chamber and rubber ball are shared on both sides of the condenser. One pump for each delivery, one for each side of the ball receiving net, secondary filter, and splitter.

3. Working principle

Select a suitable sponge rubber ball, the wet diameter of the ball is slightly larger than the inner diameter of the cooling tube (about 1-2mm), and the wet specific gravity is similar to that of water. Put the sponge rubber ball into the ball-filling room from the hand hole of the ball-filling room, the quantity is 7% ~ 13% of the number of cooling tubes in the condenser inlet chamber. Then start the rubber ball pump and open the control valve in the system. Under the action of the rubber ball pump, the rubber ball is sent into the circulating water inlet pipe under the action of a slightly higher pressure than the circulating water inlet pressure. Flow, the rubber ball enters the condenser water chamber. Because the rubber ball is a multi-dimensional microporous soft elastic body, under the effect of the pressure difference between the inlet and outlet of the circulating water, it is squeezed through the cooling tube, and the inner diameter of the cooling tube is scrubbed once, so that the dirt on the inner wall of the tube is taken out with the water flow. After passing through the condenser tube, it enters the collecting net together with the circulating water. Under the blocking of the collecting net plate, the rubber balls are separated, and then pumped out by the rubber ball conveying pump, and then enter the ball loading room. In this way, the rubber ball continuously and automatically scrubs the inner wall of the condenser cooling tube to keep it clean.

4. Introduction of each component equipment

▶ Receiving net

Receiving the ball net is one of the key components in the condenser ball cleaning process. It is installed in the outlet pipe of the circulating water of the condenser. After the circulating water and the rubber ball from the condenser pass through the collecting net, the circulating water flows out from the collecting net plate, and the rubber ball is recovered by the collecting net and is collected by the collecting net The ball outlet pipe flows into the rubber ball delivery pump and is sent to the ball loading chamber for recycling. To maintain the continuous cleaning of the sponge tube by the sponge rubber ball, it is necessary to continuously feed the rubber ball into the cleaning system. Then, the rubber balls cleaned by the cooling tube are recovered in time and used again for cleaning. The net is used to collect all the rubber balls dispersed in the cooling water, so as to reuse the equipment, so the net's collection rate is very important.

The net board of the ball net is made of stainless steel, which is resistant to corrosion, impact, and aging.

The second-generation nets designed and produced by our company adopt the latest structure and advanced foreign technology.

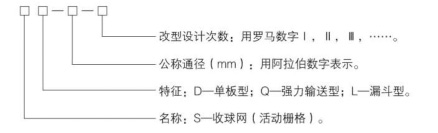

Model Description:

▶ Ball room

Ball loader is a kind of equipment used for loading, collecting, changing balls and observing the operation of rubber balls in the automatic cleaning system of rubber balls. It is mainly composed of housing, funnel, switching valve, etc., and is equipped with observation window, steam and water discharge valve, etc. The plexiglass observation window and exhaust valve are mounted on the top cover, and the drain valve is installed on the lower part of the housing. The ball packer is designed with sufficient volume to ensure that the sponge ball has room for rotation in the ball packer. The ball collecting bucket, switching valve and check valve are made of corrosion-resistant stainless steel. Due to the unique one-way valve device designed in the ball loader, the original electric door is eliminated, which not only simplifies the rubber ball cleaning system and operation, but also facilitates automatic control and improves the reliability of operation.

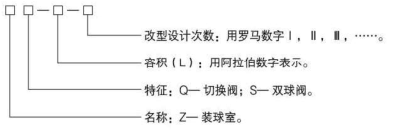

Model Description:

▶ Rubber ball delivery pump

Rubber ball pump is a special power equipment for automatic cleaning and continuous circulation of rubber balls in automatic rubber ball cleaning device. It has the characteristics of no damage to the ball, no blockage, stable operation and long service life.

The rubber ball delivery pump is a barrier-free centrifugal pump. Since the pump casing and impeller are designed in the form of wide flow channels, the phenomenon of rubber ball clogging does not occur. The pump is also called non-clogging pump. The pump uses rolling bearings, lubricated with grease, and the shaft end seal is a mechanical seal. The rear-drawing design is adopted for easy maintenance. The rubber ball pump is driven by a Y-shaped motor, adopts a cantilever beam structure, and is connected with a shaft or a back wheel. The through-flow part of the pump can be made of stainless steel with different properties and is suitable for power plants that use different water qualities as cooling water sources. In addition to being suitable for conveying rubber balls, it is also suitable for conveying mixed liquids with small abrasiveness and solid substances.

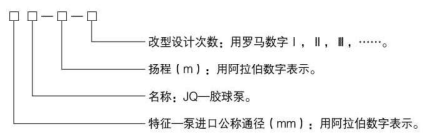

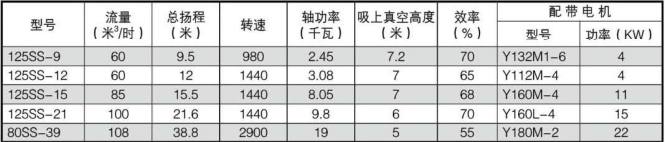

Model Description:

▶ Splitter

The splitter can divide a circulation tube into two independent tubes, for example, a tube at the outlet of the ball loader is changed to the inlet tube of two ball sprayers, then the splitter can effectively use this function. Realization; also when the two recirculation pipes are combined into one recirculation pipe, for example, the pipelines of the two receiving ports are collected into the inlet pipeline of the rubber ball pump, the splitter plays the same role.

The splitter is a three-way (pipe) valve. Through the switch of the guide plate, the rubber ball can enter the condenser on the side to be cleaned. It can also be used as the confluence of the rubber ball lead-out tube of the receiving net and the shunt tee of the rubber ball tube.

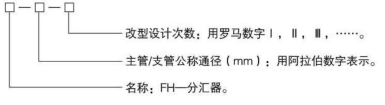

Model Description:

▶ Rubber ball

As one of the important means to improve the operating efficiency of power plants, the online condenser rubber ball cleaning system has become the standard configuration of power plants, and the quality of the rubber ball is one of the key elements of the system.

Should be wear-resistant, soft and full of elasticity, uniform material, moderate hardness, uniform air and air penetration, wet specific gravity 1.00-1.15, at a water temperature of 5-45 ℃, the inner diameter of the ball is not too large during the use period, and does not age.

In use, the diameter of the wet ball is generally 1.0-2.0mm larger than the inner diameter of the cooling tube. When there are two specifications of the cooling tube, the smaller one shall prevail.

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn