Water Treatment Equipment

Contact Us

Contact Us

产品详细

Hair collector (vertical decontamination device)

1. Product Introduction

This series of hair agglomerators are necessary equipment for circulating water treatment system. The turbid water in the swimming pool is mixed with a large amount of sediment. Stones, debris, hair, etc. are pumped out by the pump, and firstly intercepted by the hair aggregator and collected. How does the filtering and interception effect not only threaten the life of the pump, but also have a great impact on the water quality of the water purifier.

Hair aggregator is mainly used in reclaimed water treatment and swimming pool circulating water treatment system. It is used as pre-filtration treatment to remove hair, fiber and large suspended matter in the water, so as not to wrap them around the impeller of the circulating water pump, and ensure the normal operation of subsequent system equipment.

The function of the hair agglomerator is to collect the hair and fibrous substances in the water, remove the larger floating objects in the water, prevent the hair from entering the pump and the filler, affect the normal operation of the pump, block the pores of the filler, and exclude the possibility of subsequent processing equipment Adverse effects.

2. Working principle

There is a stainless steel filter inside the equipment. The raw water is filtered through the internal metal filter to block the debris in the net, and the clean water flows out. There is a sewage outlet at the bottom of the container, which can remove debris such as sand, hair, fibers, etc., and the filter can be removed from the inside for cleaning.

3. Structural characteristics

1. The hair collector is a welded steel structure.

2. A double-layer orifice plate is used in the collection room to block debris of different sizes.

3. There is a sewage outlet at the bottom of the equipment, which is convenient for sewage cleaning.

4. Scope of application

Weakly corrosive materials in petrochemical production, such as: water, ammonia, oil, hydrocarbons, etc. Corrosive materials in chemical production, such as: caustic soda, concentrated dilute sulfuric acid, carbonic acid, acetic acid, ester acids, etc. Low temperature materials in refrigeration, such as: liquid methane, liquid ammonia, liquid oxygen and various refrigerants. Light industrial food, materials with hygienic requirements in pharmaceutical production, such as: beer, beverages, dairy products, grain slurry medical supplies, etc. High-efficiency filters of various special processes, etc.

The core part of the filter is the filter core. The filter core is composed of the filter frame and the stainless steel wire mesh. The stainless steel wire mesh is a consumable part and needs special protection. For impurities, the pressure will increase and the flow rate will decrease. The impurities in the filter core should be removed in time; when cleaning the impurities, pay special attention to the stainless steel wire mesh on the filter core cannot be deformed or damaged, otherwise, the damaged filter core, The purity of the filtered media will not meet the design requirements, and compressors, pumps, instruments and other equipment will be damaged; if the stainless steel wire mesh is deformed or damaged, it needs to be replaced immediately.

5. Model meaning

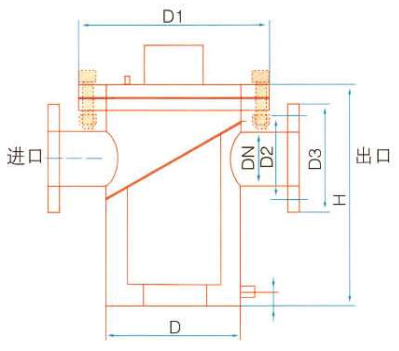

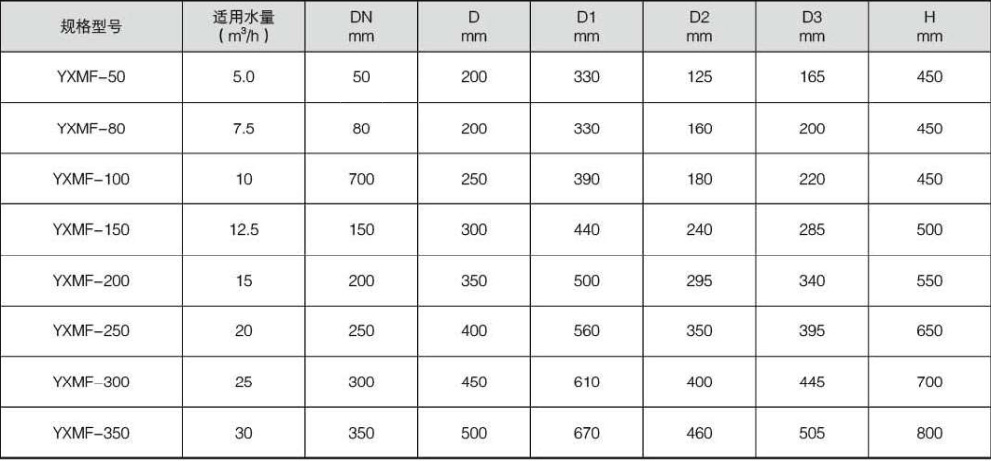

6. Product specifications and models

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn