Water Treatment Equipment

Contact Us

Contact Us

产品详细

Automatic backwash filter (fast dirt remover)

1、 Product introduction

The backwash filter overcomes many shortcomings of the traditional filter products, such as small amount of pollutants, easy to be blocked by pollutants, the filter part needs to be disassembled and cleaned, and the filter status cannot be monitored. It has the function of filtering the raw water and automatically cleaning and draining the filter element. When cleaning and draining, the system continuously supplies water, which can monitor the working status of the filter and has a high degree of automation. It covers all kinds of filtration precision requirements from 10um to 3000um, and provides various water filtration equipment for customers.

Backwash filter, operation and control can automatically clean, filter and drain without any external energy. During backwashing, the flow is continuous, and the cleaning and filtering period can be adjusted. The default cleaning and filtering time is 10-60 / s, and the water loss of cleaning and filtering only accounts for 0.08-0.6% of the filtering water; the filtering accuracy can reach 10-3000 μ m; the working pressure can reach 1.0-1.6mpa; the flow of a single set can be 4-4160m & sup3; / h.

The backwash filter can be installed in vertical, horizontal or inverted direction at any position, and can be used for water filtration in industry, agriculture, municipal power, electronics, medicine, food, printing and dyeing, construction, steel, metallurgy, papermaking and other industries.

Automatic backwash filter can be used to filter industrial water, seawater, food, pharmaceutical and other light chemical industrial wastewater, circulating water, as well as emulsion regeneration, waste oil, liquid raw materials and other filtering treatment. In the metallurgical industry, petrochemical industry and power plant water supply and drainage and circulating water systems, as well as the processes related to liquid medium filtration, the application of automatic backwash filters has become increasingly widespread. The continuous casting water system, blast furnace water system, high-pressure water descaling system for hot rolling, emulsion system and closed water circulation system introduced by modern metallurgical enterprises in China, a large number of liquid medium filtration systems are used The automatic back washing filter is used.

2. Technical parameters

Design pressure: 2.5MPa

Design temperature: 130 ℃

Filter aperture: 8-300 mesh

Filtration accuracy: 2 mm

Pressure loss: ≤ 1.2 Kpa

Blowdown time: about 23 seconds in a single cycle of backwashing

3. Features

1. The design structure is simple.

2. The backwash time is short, the flow rate and pressure loss are small.

3. Intelligent control system (PLC, PAC) control, high degree of automation.

4. The equipment can be connected with the central control system.

5. High-precision filtration, stable water quality.

6. The filter is used for life without replacement.

7. Long service life.

8. Can be applied to different raw water quality and water requirements.

9. Fewer consumables, no consumables, low operating costs, simple operation and management.

10. Automatic backwashing keeps flowing.

4. Effect

The automatic backwash filter can make industrial wastewater reach the national wastewater discharge standard, which can effectively protect the environment, and can also treat the wastewater to a standard that can be reused, which not only solves the problem of wastewater discharge, but also It can achieve reuse and save costs. The automatic backwash filter is a kind of filter that directly intercepts impurities in the water, removes suspended solids and particles in the water body, reduces turbidity, purifies water quality, and reduces the generation of system dirt, fungi, rust, etc. Equipment to improve water quality and protect the normal operation of other equipment.

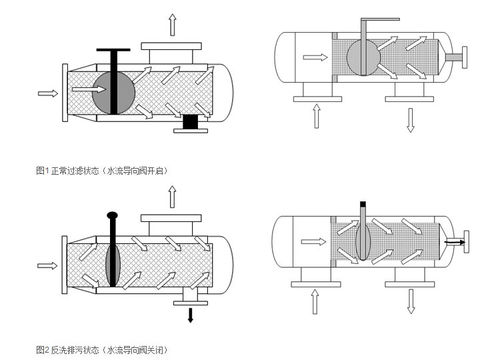

5. Working principle

Water enters through the inlet, firstly through the coarse filter to filter out larger particles of impurities, and then to the fine filter. During the filtration process, the fine filter gradually accumulates the dirt and impurities in the water to form a filter impurity layer, which is deposited on the inner side of the fine filter, so a pressure difference is formed on the inner and outer sides of the fine filter .

When the pressure difference of the filter reaches the preset value, the automatic cleaning process will begin. During this time, the supply of clean water will continue to flow, the cleaning valve will open, and the water pressure in the cleaning chamber and the suction device will drop significantly. Due to the pressure difference, a suction force is generated between the suction pipe and the cleaning chamber through the suction nozzle to form a suction process. At the same time, the electric motor drives the suction pipe to make a spiral movement in the axial direction. The combination of axial movement and rotary movement of the dirt suction device completely cleans the entire inner surface of the filter screen. The entire flushing process takes only tens of seconds. The drain valve closes at the end of cleaning. The filter is ready for the next flush cycle.

6. Cleaning characteristics

a. The automatic recoil sewage filter uses multiple filter cartridges to filter, the effective filtration area is large, and the pressure loss is small. The design filtration area is 3 to 5 times of the import and export area.

b. Convenient maintenance and maintenance of automatic recoil sewage filter: set up manhole for inspection, easy to install and remove filter cartridge, backwash filter

c. The automatic recoil sewage filter adopts the structure of multi-filter cartridge filtering and cleaning one by one, and the water supply is uninterrupted during cleaning.

d. Program control of automatic recoil sewage filter: the parameters of the system can be set according to the actual situation of the user site.

e. Advanced control system of the backwash filter: the control system has high accuracy, and its working mode and operating state can be adjusted according to different water quality to improve its ability to adapt to water quality.

f. Convenient control method of backwashing filter: differential pressure / time control or separate control, which can be selected at will according to actual working conditions and needs, automatic operation; at the same time, manual / automatic conversion switch is set, the control method can be preset, and Can achieve electrical interlock,

g. The backwash filter is equipped with local control, if necessary, a remote transmission control switch can be set to achieve local operation and remote control operation.

h. The backwash filter retains functions such as operation status output and fault alarm output to ensure that the equipment is used under the safe and reliable conditions.

Backwash filter has strong filtering capacity and large flow rate: due to structural limitations, the maximum flow rate can only reach 380L / min. The filter can reach 800L / min or more. Fully automatic filter, filter, comprehensive water processor, electronic descaler backwash filter with high filtration accuracy: there are two or more sets of filter elements in the backwash filter, the flow area is large, the original pressure loss is small, and Achieving high-flow and high-precision filtration (25 m, 40 m), traditional filters are difficult to achieve. The backwash filter quantifies the degree of pollution: the filter can be equipped with pressure gauges K1, K2, P = K1-K2 at the inflow port Pi port and the outflow port Po port, which quantitatively reflects the filter being polluted The degree of easy to clean at any time, the traditional filter does not have this function.

7. Product selection

When selecting the filter, please consider the following factors:

1. Water treatment

2. The pipeline pressure of the system

3. Filtration accuracy required by users

4. Filter the concentration of suspended matter in impurities

5. Relevant physical and chemical properties of filter media

6. Special purpose filters

8. Special Purpose

Can be designed according to user needs, producing filters of various pressure ranges; through special processes to produce filters with a temperature above 95C, for filters that need to work in cold conditions, a special filter control system will be used; for seawater corrosion With strong characteristics, special materials such as nickel and titanium alloys are selected, and the filters are specially processed; according to the user's specific working conditions and requirements, targeted solutions can be provided.

9. Application range

Iron and steel: used for water treatment and filtration in raw material yards, sintered pellet plants, filtration of cooling water in blast furnaces, rolling mills, continuous casting machines, etc., and filtration of impurities in high-pressure water dephosphorization systems.

Automobiles: Coating production lines are widely used in the manufacture of water and treatment systems for automobiles, tractors, motorcycles, and engines.

Power plant: It is used for the precision pretreatment of high-purity water preparation in power plant boilers. It is used for the filtration of generator cooling water and sealing water. When the water consumption of the 13-4 system is extremely large, it can be used as a side filter treatment and a full filter treatment.

Petrochemical: By-pass filtering treatment in the circulating water field, which can be used as a single machine or multiple models in parallel for main treatment, instead of filtering the filtering material, reducing the filtering load of the filtering material, avoiding a large amount of water consumption for washing and saving costs.

Agricultural gardens and paper mills: In the system with nozzles and nozzles, to reduce equipment clogging and wear caused by impurities, it is necessary to select high-precision and high-automation filtration products machinery, food or other: automatic, precision filtration of the system, use To prevent the cooling water system from clogging.

Mine: Filter sprinkler water underground to ensure that the system is working properly.

Water supply and sewage treatment: used in pretreatment system to improve system operation efficiency.

Widely used in drinking water treatment, construction circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment, construction, steel, petroleum, chemical industry, electronics, power generation, textile, papermaking, food, sugar , Pharmaceuticals, plastics, automotive industry and other fields.

10. Manufacturing Process

1. Leading product structure and functional design, compact structure, original filter shell integral molding and processing technology, to avoid various drip caused by welding of steel filter shell;

2. The high-strength nodular cast iron material has excellent anti-corrosion performance and prolongs the service life of the product;

3. Proprietary filter element design and manufacturing technology, high-precision filter element will never wear, pressure inspection will never be deformed, and factory precision test meets user requirements;

4. The coarse and fine filters are made of stainless steel welded mesh, and the screen plate and screen form an internal and external double-layer structure; due to the active cleaning method for the filter element, it enhances its anti-interference ability and is thoroughly cleaned, especially suitable for poor water quality conditions .

11. Installation method

1. The installation only needs to be connected to the pipeline according to the direction of the water indicated by the arrow on the equipment cylinder;

2. The design and installation should try to consider that the sewage outlet is at the lower part to facilitate the smooth discharge of debris;

3. The sewage pipe is connected to the drainage ditch nearby, and the sewage should be kept smooth;

4. In order to facilitate the observation of system working conditions and daily operations, pressure gauges and manual valves should be installed at the inlet and outlet;

5. When discharging sewage, flush the filter for 10-60 seconds by opening and closing the valve according to the sewage situation;

6. How to use the microcomputer controller:

(1) Setting method of outlet water pressure value: After the system is in operation, observe the equipment inlet water pressure value, and then adjust the value of the outlet water power contact pressure gauge to be less than the inlet water pressure value of 0.06-0.08MPa. For example, if the inlet water pressure is 0.2MPa, the value of the outlet water power contact pressure gauge can be adjusted between 0.32-0.34MPa.

(2) Then turn on the power of the microcomputer and turn on the power switch on the control panel.

(3) If the outlet pressure is lower than the set pressure value at this time, the equipment remains in working state, the working indicator lights, the automatic actuator opens the valve plate, and the sewage solenoid valve (or electric valve) closes.

(4) If the outlet pressure is lower than the set pressure value, the device enters the backwash state, the backwash indicator lights, the automatic actuator closes the valve plate, and the sewage solenoid valve (or electric valve) opens. After the backwashing process is delayed for 2-4 minutes, it returns to the working state. If the water outlet pressure is higher than the set pressure value at this time, the equipment maintains the normal water outlet state; if the water outlet pressure is still lower than the set pressure value, the equipment works for 2-4 minutes and backwashes for 2-4 minutes. The outlet pressure value is higher than the set pressure value.

(5) Backwashing is performed with double rubber ring seals (or PTFE packing) between the ram shaft and the equipment cylinder. If water leakage occurs during use, use a small wrench to tighten the three screws on the gland properly and evenly. Circle, subject to no water leakage. If the gland is pressed to the bottom and still cannot solve the water leakage phenomenon, you need to replace the new seal ring or packing (the specifications of the seal ring are subject to the random spare model).

12. Installation attention

The selection of filter specifications should match the installation pipeline. When the flow rate of the filter cannot meet the pipeline requirements, two (or more) filters can be installed in parallel, or by-pass treatment.

The filter should be installed as far as possible in the place where the system is to be protected. The low pressure at the inlet affects the use, so it should also be installed near the pressure source.

The filter should be installed in series in the pipeline system. In order to ensure uninterrupted water supply to the system during shutdown and maintenance, it is recommended to set a bypass in the system. Both the inlet and outlet of the filter and the bypass should be provided with shut-off ball valves. Where there is a possibility of backflow, a check valve should be installed at the outlet of the filter.

Please pay attention to the temperature of the water flowing through the automatic self-cleaning filter when selecting the model.

The installation site has three-phase 380V power frequency alternating current (three-phase four-wire system). Sewage pipe does not exceed 5 meters to avoid back pressure.

DC system should pay attention to filtering accuracy, pretreatment and pressure matters, intermittent system should be careful to use timing control type.

Reasonably choose the installation environment, pay attention to waterproof, rain and moisture.

Note: The backwash system will stop running for a long time or seasonally. Before the system stops running, add an appropriate amount of corrosion inhibitor to the water and take measures to protect the system from water corrosion.

13. Use attention

The device has been debugged before leaving the factory, and the user can directly run it when using it. When the operating parameters of the equipment can not meet the user's requirements, the user can adjust each parameter according to the actual working conditions, and select the manual control and automatic control methods to work accordingly.

When running for the first time, follow the steps below:

Check whether the filter is in normal working condition:

Check whether the connections of the filter are firm.

Check that the electric control box of the filter is dry.

Turn on the power, the green power indicator light is on, which means that the electric control part of the filter is in normal working state, and the equipment can be put into trial operation.

Note: Keep your hands dry when plugging in the power supply. At the same time, keep the electric controller partially dry during the working process of the filter. No water can enter the electric controller.

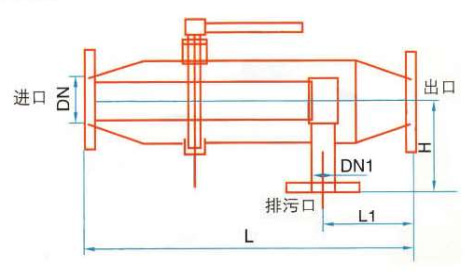

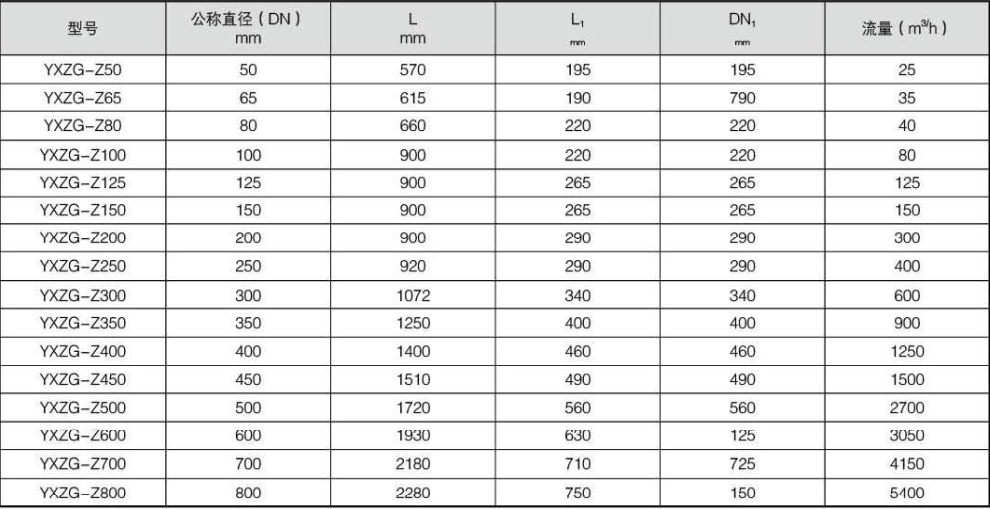

14. YXZG-Z straight-through specifications and size parameters

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn