Water Treatment Equipment

Contact Us

Contact Us

产品详细

Multi-media filter

The multi-media filter is a process that uses one or several filter media to pass high-turbidity water through a certain thickness of granular or non-granular materials to effectively remove suspended impurities and clarify the water. The filter material is quartz sand, anthracite, manganese sand, etc. It is mainly used for water treatment to remove turbidity, soften water, and pre-treatment of pure water. The effluent turbidity can reach below 3 degrees.

1. Product Introduction

The meaning of filtration. In the process of water treatment, filtration generally refers to the process of intercepting suspended impurities in water with a filter layer of quartz sand, anthracite, etc., so that the water is clarified. The porous material used for filtration is called filter material, and quartz sand is the most common filter material. The filter material has a variety of granular, powder and fibrous. Commonly used filter materials are quartz sand, anthracite, activated carbon, magnetite, garnet, porous ceramics, plastic balls, etc.

Multi-media filter (filter bed), which uses more than two kinds of media as the filter of the filter layer, in the industrial circulating water treatment system, to remove impurities in the sewage, adsorb oil, etc., so that the water quality meets the requirements of recycling . The role of filtration is mainly to remove suspended or colloidal impurities in water, especially to remove tiny particles and bacteria that cannot be removed by precipitation technology. BOD5 and COD also have a certain degree of removal effect.

1) Equipped with its own backwashing device, no additional backwashing pump is required

2) Water can be supplied directly to users without additional secondary pumps to reduce secondary pollution

3) Equipped with sand remover

4) Long filtration cycle, complete removal of iron and manganese

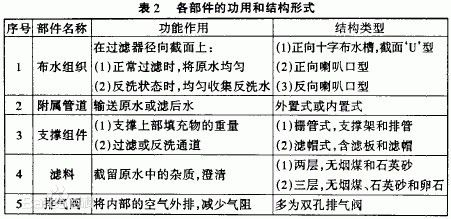

2. Structure Introduction

Multi-media filters are widely used in the process of water treatment. Multi-media filters are mainly composed of the following parts: supporting pipelines and valves.

The filter body includes:

① Cylinder;

② Backwash the trachea;

③Water distribution components;

④Support assembly;

⑤ Filter material;

⑥ Exhaust valve (external), etc.

3. Effect

Remove mud, suspended solids, colloids and other impurities in the water and algae and other organisms, reduce mechanical damage and pollution to the reverse osmosis membrane element.

4. Composition of inner filter layer

The multi-media filter material in the filter is high-quality uniform-grained gravel, quartz sand, magnetite, anthracite and other filter materials. These filter materials are scientifically and orderly distributed in the filter tank according to their specific gravity and particle size, such as small specific gravity Anthracite with a slightly larger particle size is placed in the uppermost layer of the filter bed, quartz sand with moderate specific gravity and smaller particle size is placed in the middle layer of the filter bed, and gravel with a larger specific gravity and larger particle size is placed in the lowermost layer of the filter bed. Such a ratio ensures that the filter does not produce chaotic layers during backwashing, thereby ensuring the retention capacity of the filter material.

5. Principle

Multi-media filter (also called mechanical filter) is a typical multi-media filter with layered anthracite, sand, finely divided garnet or other materials as the bed.

The top layer of the bed is composed of the lightest and coarsest grade materials, while the heaviest and finest grade materials are placed in the lower part of the bed. The principle is to filter by depth-larger particles in the water are removed on the top layer, and smaller particles are removed deeper in the filter media. So that the water quality reaches the standard after coarse filtration.

The equipment is pressure type, the principle is that when the raw water passes through the filter material from top to bottom, the suspended matter in the water is trapped by the surface of the filter layer due to adsorption and mechanical choke; when the water flows into the middle of the filter layer, due to the filter layer The sand particles are arranged closer, so that the particles in the water have more chances to collide with the sand particles, so the floc, suspended matter and sand particles in the water adhere to each other, and the impurities in the water are trapped in the filter material layer, thereby obtaining clear water quality. The filtered suspension of effluent can be below 5 mg / L.

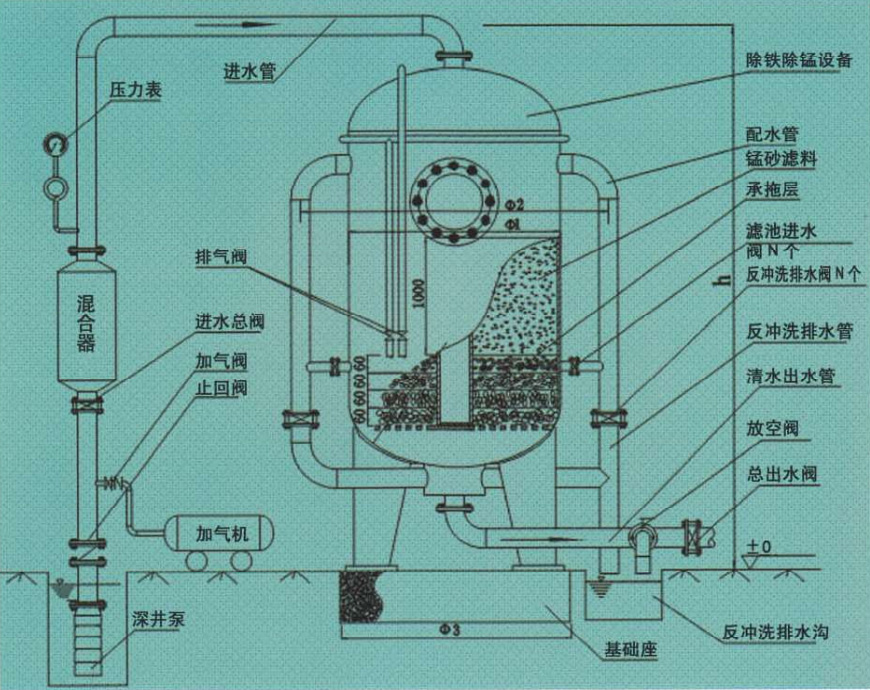

G series multi-media filters are mainly used in groundwater high-speed iron and high-manganese areas, in order to solve the groundwater as the water source, the iron and manganese removal treatment device is required. The device adopts the principle of oxidative iron removal and manganese removal, and uses oxygen in the air to remove water The Fe2 + and Mn2 + ions are oxidized into water-insoluble Fe3 + and Mn2, and then combined with the natural manganese sand filler in the device to remove iron and manganese ions in the water.

The reaction formula of iron-manganese oxidation is as follows: iron oxidation: air: 4Fe2 ++ 3O2 + 6H2O = 4Fe (OH) 3 ↓

Manganese sand: MnO • Mn2O7 + Fe2 ++ 2O2 + 6H2O = 3MnO2 + 4Fe (OH) 3 ↓

Manganese oxidation: Mn2 ++ O2 = MnO2 ↓

Manganese sand: Mn2 ++ MnO2 • H2O = MnO2 • MnOH2O + 2H +

6. Features

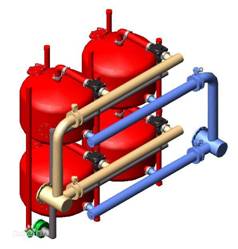

1. Porous media filters are widely used in water treatment processes and can be used alone, but most are used as pre-filtration for advanced water treatment (exchange resin, electrodialysis, reverse osmosis).

2. Multi-media filter is a commonly used pretreatment device for deep purification of water quality, and different filter materials can be added according to process requirements.

3. Multi-media filter material can be made of glass steel, A3 steel anti-corrosion or rubber lining, all stainless steel. There are two forms of operation: full-automatic and manual. The automatic control adopts the automatic controller and gas and liquid valve imported from the United States. It is easy to operate and easy to maintain. It is widely used in pretreatment devices of water treatment processes in various industries .

4. The filter material of the multi-media filter (including double filter material filter) should have sufficient chemical stability, the relative density and particle size of each medium should be different, and the double-layer filter material composed of anthracite and quartz sand should be filtered The relative density of the anthracite used in the filter is 1.4-1.6, the particle size is 0.8-1.8mm, the relative density of the quartz sand is 2.6-2.65, the particle size is 0.5-1.2mm; in addition to the above two filters Heavy ores such as manganese sand and magnetite can be used, with a relative density of 4.7-5.0 and a particle size of 0.5-4mm.

5. Aeration part: No need to pump chemicals and catalysts, just add a small amount of air, which can reduce operating costs.

6. The main part of the equipment is a device that integrates strong oxidation reaction, separation sand remover, grouping suspension tank and other processes into one, with unique structure.

7. Filter part: Since the filter has its own backwashing device, it does not need to be equipped with a backwashing pump, which can reduce the project footprint and project investment.

8. The backwashing strength of the pressure filter is high, which makes the filter layer flush evenly and cleanly, the backwashing time is short, the filtering period is long, and the service life of the filter material is extended.

9. The equipment can directly supply water to users and the pipe network, without the need to be equipped with clear water pools and secondary pumping stations, reducing equipment investment and avoiding secondary pollution.

7. Structure

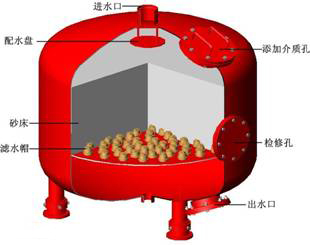

The multi-media filter is mainly composed of a filter body, supporting pipelines and valves.

The filter body mainly includes the following components: simplified; water distribution component; support component; backwashing air tube; filter material; exhaust valve (external) and so on.

8. Filter selection

(1) Must have sufficient mechanical strength to avoid rapid wear and breakage during backwashing;

(2) The chemical stability is better;

(3) It does not contain substances harmful to human health and toxic substances, nor substances harmful to production or affecting production;

(4) As for the selection of filter materials, filter materials with large adsorption capacity, large interception capacity, high water production and good effluent quality should be used as much as possible.

In the filter material, the pebbles mainly play a supporting role. During the filtering process, due to its high strength, the gap between each other is stable, the gap is large, and the pores are large, which is convenient for the water after the filter to pass smoothly during the normal washing process; similarly, the backwash During the process, backwash water and backwash air can pass through smoothly.

In the conventional configuration, the pebbles are divided into four specifications, and the bedding method is from bottom to top, and then the size is large.

The relationship between the particle size of the filter material and the filling height

The ratio of the height of the filter bed to the average particle size of the filter material is 800 to 1,000.

The size of the filter material is related to the filtration accuracy.

The following table shows the function and structure of each component.

9. Sand filter composition

Quartz sand filter structure is divided into filtration system and control system. The filtration system is usually composed of high-efficiency filtration units, three-way automatic valves, water inlet and outlet pipes, and sewage pipes. The high-efficiency filter unit includes various filter media. The control system is usually composed of PLC timing controller, differential pressure controller, electromagnetic three-way valve and control pipeline.

10. Type

Common filter materials for multi-media filters are: anthracite, ceramsite, quartz sand, activated carbon, etc.

▶ Multimedia

Multi-media filters used in water treatment, common are: anthracite-quartz sand-magnetite filter, activated carbon-quartz sand-magnetite filter, activated carbon-quartz sand filter, quartz sand-ceramic filter Wait.

The filter layer design of the multi-media filter, the main considerations are:

1. Different filter materials have a large density difference to ensure that the mixing layer phenomenon will not occur after backwashing disturbance.

2. Select the filter material according to the purpose of water production.

3. Particle size The particle size of the lower filter material is smaller than that of the upper filter material to ensure the effectiveness and full utilization of the lower filter material.

In fact, taking a three-layer filter bed as an example, the upper layer of filter material has the largest particle size and is composed of light-weight filter material with low density, such as anthracite, activated carbon; the middle layer of filter material has a medium particle size and a medium density, generally composed of quartz sand; the lower layer The filter material consists of heavy filter material with the smallest particle size and the highest density, such as magnetite. Due to the limitation of density difference, the filter material selection of the three-layer media filter is basically fixed. The upper filter material plays a role of coarse filtration, and the lower filter material plays a role of fine filtration. In this way, the role of multi-media filter bed is fully exerted, and the effluent water quality is significantly better than that of a single-layer filter material.

For drinking water, it is generally prohibited to use anthracite, resin and other filter materials.

▶ Quartz sand

Quartz sand filter is a kind of filter using quartz sand as filter material. It can effectively remove suspended matter in water, and has obvious removal effect on colloid, iron, organic matter, pesticide, manganese, bacteria, virus and other pollutants in water. It has the advantages of low filtration resistance, large specific surface area, strong acid and alkali resistance, oxidation resistance, PH application range of 2-13, good pollution resistance, etc. The unique advantage of quartz sand filter is that it is optimized by filter material and filter The design of the filter realizes the adaptive operation of the filter, and the filter material has a strong self-adaptability to the raw water concentration, operating conditions, pre-treatment process, etc. Ensure the quality of the effluent water under various operating conditions, the filter material is fully dispersed during backwashing, and the cleaning effect is good. The sand filter has the advantages of fast filtration speed, high filtration precision and large interception capacity. Widely used in electric power, electronics, beverages, tap water, petroleum, chemical industry, metallurgy, textile, papermaking, food, swimming pool, municipal engineering and other process water, domestic water, circulating water and wastewater pretreatment fields.

Quartz sand filter equipment has a simple structure, can realize automatic control, large processing flow, less backflushing times, high filtration efficiency, low resistance, and convenient operation and maintenance.

▶ Ferromanganese

Filled binary filter material of refined manganese sand and quartz sand to remove iron and manganese in water. Generally only used in the pretreatment of raw water containing iron and manganese.

▶ Activated carbon

The filter material is activated carbon, which is used to remove color, taste, residual chlorine and organic matter. Its main function is adsorption. Activated carbon is an artificially made adsorbent.

The filter material is activated carbon, which is used to remove color, taste, residual chlorine and organic matter. Its main function is adsorption. Activated carbon is an artificially made adsorbent.

Activated carbon filters are widely used in the pretreatment of domestic water and water in the food industry, chemical industry, electric power and other industries. Activated carbon has a well-developed pore structure and a huge specific surface area, so it has a strong adsorption capacity for dissolved organic matter in water, such as benzenes and phenols, and is difficult to remove organics by biological and chemical methods Contaminants, such as chroma, odor, surfactants, synthetic detergents and dyes, have good removal effects. Granular activated carbon has a removal rate of Ag ^ +, Cd ^ 2 +, CrO4 ^ 2-plasma in water of more than 85%. After passing through the activated carbon filter bed, the suspended solid in water is less than 0.1mg / L, the COD removal rate is generally 40% to 50%, and the free chlorine is less than 0.1mg / L.

11. Backwashing

Backwashing of the filter mainly means that the filter layer retains and adsorbs a certain amount of debris and stains after the filter is used for a certain period, which makes the quality of the effluent of the filter drop.

▶ Main characterization

After the normal filtration of the filter, the water quality deteriorates, the pressure difference between the inlet and outlet pipes increases, and at the same time, the flow rate of a single filter decreases.

▶ Principle

The water flow reversely passes through the filter layer to expand and suspend the filter layer. The filter layer is cleaned by the shear force of the water flow and the collision friction of the particles to remove the dirt in the filter layer and discharged with the backwash water.

▶ Necessity

(1) During the filtration process, suspended matter in the raw water is trapped and adsorbed by the filter layer and continuously accumulates in the filter layer, so the pores of the filter layer are gradually blocked by dirt, forming a filter cake on the surface of the filter layer and filtering the water head The loss is increasing. When a certain limit is reached, the filter material needs to be cleaned to restore the working performance of the filter layer and continue to work.

(2) Due to the increase in head loss during filtration, the shear force of the water flow on the dirt adsorbed on the surface of the filter material becomes larger, and some of the particles move to the lower layer of filter material under the impact of the water flow, which will eventually cause suspended matter in the water The content continues to rise and the water quality deteriorates. When the impurities penetrate the filter layer, the filter loses its filtering effect. Therefore, to a certain extent, the filter material needs to be cleaned in order to restore the dirt holding capacity of the filter material layer.

(3) The suspended matter in the sewage contains a large amount of organic matter. If it stays in the filter layer for a long time, it will lead to the enrichment and reproduction of bacterial microorganisms in the filter layer.

12. Parameter analysis

▶ Parameter control

(1) Swelling height: During backwashing, in order to ensure that the filter material particles have sufficient clearance to allow dirt to quickly exit the filter layer with water, the filter layer expansion rate should be greater. However, when the expansion rate is too large, the number of particles of the filter material per unit volume decreases, and the chance of particle collision also decreases, so it is not good for cleaning. Double-layer filter material, the expansion rate is 40%-50%.

Note: During the production operation, the filling height and expansion height of the filter material are randomly checked, because part of the filter material will be lost or worn during the normal backwashing process and needs to be supplemented. The relatively stable filter layer has the following advantages: ensuring the stability of the filtered water quality and ensuring the effect of backwashing.

(2) Backwash water volume and pressure: General design requirements, the strength of backwash water is 40 m3 / (m2 · h), and the pressure of backwash water is ≤0.15 MPa.

(3) Backwash air volume and pressure: the strength of the backwash air is 15 m / (m • h), and the pressure of the backwash air is ≤0.15 MPa.

Note: During the backwashing process, the incoming backwashing air is collected at the top of the filter, and most of it should be discharged through the double-hole exhaust valve. In daily production. The patency of the exhaust valve needs to be checked frequently, which is mainly characterized by the freedom of valve ball lifting.

▶ Gas-water combination

(1) First flush with air, then backwash with water: first reduce the water level of the filter to 100 mm above the surface of the filter layer, let the air in for a few minutes, and then backwash with water. It is suitable for filters with heavy surface pollution and light internal pollution.

Note: The corresponding valve must be closed in place; otherwise, when the water level drops below the surface of the filter layer, there is no water infiltration on the upper part of the filter layer. During the up and down disturbance of the particles, the dirt cannot be effectively discharged, but will go deep into the filter layer mobile.

(2) Combined backwashing of air and water: air and backwashing water are simultaneously fed from the lower part of the static filter layer. The air merges in the sand layer during the ascent to form large bubbles, which become small bubbles when meeting the filter material. It has a scrubbing effect on the surface of the filter material; backwashing the water to loosen the filter layer makes the filter material in a suspended state, which is conducive to the scrubbing of the filter material by the air. The expansion effects of backwash water and backwash air are superimposed on each other, and the effect is stronger than when it is carried out alone.

Note: The backwash pressure of water is different from the backwash pressure and strength of air. Pay attention to the order to prevent backwash water from entering the air pipe.

(3) After the gas-water combined backwash is completed, stop entering the air, keep the backwash water at the same flow rate, and continue to rinse for 3 min ~ 5 min to remove air bubbles left in the filter bed.

Note: You can pay attention to the status of the top two-hole exhaust valve.

13. Cause Analysis

(1) The dirt trapped on the surface of the filter layer cannot be effectively removed within a certain period. In the subsequent backwashing process, if the distribution of the backwashing air is uneven, the expansion height will be uneven. Scrubbing of the air scrubbing, where the amount of scrubbing is small, impurities such as oil stains on the surface of the filter material cannot be effectively removed. After the next normal filtration cycle, the local load increases, the impurities will sink into the interior from the surface, and the pellets gradually increase Large, and at the same time extend into the filling depth of the filter until the entire filter fails.

Remarks: In actual operation, the phenomenon of uneven backwashing air often occurs, mainly due to the perforation of the bottom gas distribution pipe, the blockage or damage of the local filter cap, or the deformation of the grid tube spacing.

(2) The particles of the filter material on the surface of the filter layer are fine, there is less chance of collision with each other during backwashing, and the momentum is small, so it is not easy to clean. The attached sand particles tend to form small mud balls. When the filter layer is re-graded after backwashing, the mud ball enters the lower filter material, and continuously moves deeper as the mud ball grows.

(3) The oil contained in the raw water is trapped in the filter, after being backwashed and the residual part, accumulated over time, is the main factor that causes the filter material to solidify.

When to perform backwashing can be determined according to the characteristics of raw water quality and effluent water quality requirements, using criteria such as limited head loss, effluent water quality or filtration time.

14. Matters needing attention

(1) The parallel tolerance between the outlet tank and the filter plate is required to be no more than 2 mm.

(2) The level and unevenness of the filter plate are less than ± 1.5 mm. The structure of the filter plate is optimized for overall processing. When the diameter of the cylinder is large, or when it is restricted by raw materials and transportation, it can also be formed by splicing two petals.

(3) The reasonable treatment of the joint parts of the filter plate and the cylinder is particularly important for the air backwashing link.

① In order to eliminate the radial gap between the filter plate and the barrel caused by errors in the processing of the filter plate and the rolling of the barrel, the arc-shaped ring plate is generally welded in sections. The contact parts must be fully welded.

②The radial gap treatment method of the central pipe and filter plate is the same as above.

Note: The above measures ensure that filtration and backwashing can only be communicated through the gap between the filter cap or the discharge pipe. At the same time, the distribution uniformity of the backwash and filter channels is also guaranteed.

(4) The radial error of the through hole processed on the filter plate is ± 1.5 mm. The increase in the matching size between the filter cap guide rod and the through hole of the filter plate is not conducive to the installation or fixation of the filter cap. The processing of through holes must use mechanical equipment.

(5) The material of the filter cap, nylon is the best, followed by ABS. Due to the filter material added at the top, the squeeze load on the filter cap is extremely high and the strength is required to be high to avoid deformation. The contact surface (upper and lower surfaces) of the filter cap and the filter plate should be added with elastic rubber pads.

15. Application Field

▶ Pretreatment of reverse osmosis, electrodialysis, ion exchanger, ultrafiltration and other systems

▶ Pre-filtration treatment of raw water in power generation, chemical industry, paper making, beverages, etc.

▶ Decolorization and deorganization of water supply in chemical plants

▶ Domestic water pretreatment

▶ Industrial water treatment

▶ Swimming pool water treatment

▶ Circulating water side filter system

▶ Reducing turbidity and removing color of surface water and groundwater

▶ Waste water treatment

16. Technical performance

Gas-water mixing time: 3-5 minutes; filter tank filtration speed, 0-14 m / h; backwash strength, 16-18 l / m² sand; filter layer thickness: 1.0-1.2 m; inlet pressure ≥0.06 MPa, Equipment withstand pressure: 0.06-0.3MPa, 0.3-0.6MPa, 0.6-1.0MPa.

Scope of application: Inlet water contains iron ≤20 mg / L, manganese ≤10 mg / L, effluent ≥0.3 mg / L, manganese ≥0.1 mg / L.

17. Technical parameters

▶ Raw water iron content 5-20㎎ / L manganese content 1-9㎎ / L

▶ After filtering, the effluent contains iron < 0.3㎎ / L manganese content < 0.1㎎ / L

▶ Working pressure 0.4-1MPa

▶ Product specification 5-200m³ / L

18. Process structure and flow chart of multi-media filter

19. Specifications, Models and Dimensions

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn