Water Treatment Equipment

Contact Us

Contact Us

产品详细

Comprehensive water processor

1. Product Introduction

With the combination of high-frequency technology and filtration technology, Youxin has designed and manufactured a variety of functional types (A, B, C, D, E, F) full-range integrated water processor.

2. Equipment working principle

The full-range integrated water processor first adopts high-frequency technology, using the action of high-frequency electric field force to activate the water, the movement speed of Ca2 + and Mg2 + ions in the water is reduced, the number of effective collisions with the CO32-, SO42- plasma in the water is reduced, and the electrostatic attraction is reduced , So the heated wall or the surface of the tube cannot scale, so as to achieve the purpose of anti-scaling. The high-frequency electromagnetic field increases the water's permeability and solubility, and after penetrating the weak link of scale on the metal surface to the metal surface longitudinally, it starts to penetrate horizontally along the surface of the metal and the ditch, so that the scale is detached from the metal surface in the form of a sheet, so as to achieve The purpose of the purchase. The micro-electric environment can restrain the growth of microorganisms and destroy their living environment. In addition, the active oxygen free radicals generated during the operation of the equipment have the function of damaging biological macromolecules, changing the biological field of bacteria and algae survival, etc. to achieve sterilization and algae elimination. purpose. Secondly, the composite filtration system (surface filtration principle, multi-media composite layer, electric energy magnetic field effect) is used to adsorb and capture the suspended solids in the water, such as iron and manganese ions, bacterial algae colloids, etc., and discharge the system to achieve ultra-clean filtration.

3. Product technical parameters

(1) Water temperature: ≤150 ℃

(2) Power supply: 220V, 60Hz

(3) Power: 50-600W

(4) Applicable water quality: total water quality hardness <700mg / L (calculated as CaCO3)

(5) Working environment temperature: temperature 5 ~ 55 ℃

(6) Water head loss: ≤1.5m water column

(7) Connection flange standard: GB9119.8-88

4. Installation and operation requirements

(1) The whole integrated water processor should be installed before the water equipment that needs to be protected, as close as possible to the water inlet of the water equipment.

(2) When installing a full-range integrated water processor in a non-circulating system, a check valve must be installed at the rear of the product.

(3) The new system can be installed directly. If the system to be installed is seriously fouled (scale thickness ≥3mm), the pipeline should be cleaned first to prevent the old scale from falling off and blocking the pipeline after treatment.

(4) It is better to set bypass during installation to avoid affecting system operation during maintenance.

(5) This product should be installed indoors to prevent the controller from getting wet, and waterproof devices should be added for outdoor installation.

(6) There should be adequate space around the controller of the integrated water processor and the upper part of the equipment for maintenance.

(7) Do not force the controller during installation and transportation.

(8) Please configure the power supply according to the voltage and power indicated on the product nameplate.

5. Backwash operation requirements

(1) The installation of this equipment must use the form of a three-valve bypass pipe to meet the requirements of backwashing.

(2) Observe the pressure gauge value at the inlet and outlet. When the pressure difference is large (2-3 times greater than the newly installed and just backwashed), the backwash should be performed once. When the water quality is poor, the backwash frequency should be increased. . The time of each backwash depends on the quality of the discharged sewage, which is usually 30 seconds.

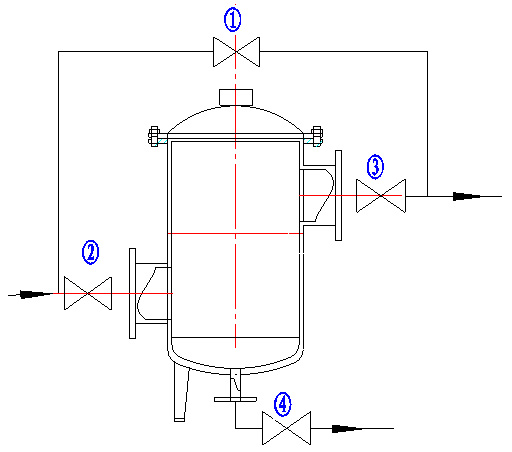

(3) Backwash operation procedure: (as shown below)

a. Open the bypass valve ①

b. Close the inlet valve ②

c. Open the drain valve ④

d. Turn off the power for sewage operation

e. Reverse to normal state (①, ④ valve closed; ②, ③ valve opened, power on)

6. Other matters needing attention

(1) The product has been debugged before leaving the factory. It can work when connected to the power supply during operation. The red and green lights are on, indicating normal work, otherwise the manufacturer is notified to repair.

(2) Sewage discharge should be timely, and the operation status of the equipment should be grasped at any time.

(3) The main unit must not be disassembled without authorization, otherwise the manufacturer will not be responsible for maintenance.

(4) This product is generally guaranteed for 12 months with lifetime maintenance.

(5) The customer should not disassemble, modify, or replace parts without the consent of the customer, otherwise the manufacturer will not guarantee the warranty, and if it is damaged, it will not be repaired.

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn