Water Treatment Equipment

Contact Us

Contact Us

产品详细

Fully automatic demineralized water equipment

Brief introduction of automatic softening water unit

Automatic water softening equipment is composed of automatic water softening controller (US FLECK Fleck, AUTOTROL Atuzu controller, domestic Runxin controller), resin tank (usually FRP resin tank and stainless steel resin tank), strong acid type sodium ion Composition of resin and salt tank. Fully automatic water softening equipment has the characteristics of small size, simple operation, and automatic operation without manual operation. It has been widely used in industrial boilers, cooling circulating water, steelmaking, steel rolling, large transformers, underground alkaline water treatment, civil hot water boilers, etc. occasion.

1. The standard work flow of fully automatic water softening equipment mainly includes:

Five processes: water preparation (sometimes called product water, the same below), backwashing, salt absorption (regeneration), slow flushing (replacement), and quick flushing. All the processes of different demineralized water equipment are very close, but there may be some additional processes due to different actual processes or control needs. Any demineralized water equipment based on sodium ion exchange is developed on the basis of these five processes (among them, fully automatic demineralized water equipment will increase the brine reinjection process).

2. Performance characteristics of automatic water softener:

Water production-water containing calcium and magnesium ions (Ca2 +, Mg2 +), when flowing through the resin layer under a certain pressure and a certain flow rate, because the binding capacity of calcium and magnesium ions (Ca2 +, Mg2 +) and resin is greater The binding capacity of sodium ions (Na +) and resin, therefore, calcium and magnesium ions (Ca2 +, Mg2 +) in water exchange with sodium ions (Na +) on the resin, and calcium and magnesium ions (Ca2 +, Mg2 +) are adsorbed by the resin. In this way, the water flowing out of the resin layer no longer contains calcium and magnesium ions (Ca2 +, Mg2 +).

Salt water suction-salt water enters the resin tank from the salt tank through the "jet salt suction device" of the automatic control valve.

Slow rinsing (displacement)-high concentration sodium ions (Na +) in the brine exchange with calcium and magnesium ions (Ca2 +, Mg2 +) on the resin. Calcium and magnesium ions (Ca2 +, Mg2 +) are exchanged and discharged with water The sodium ions (Na +) in the brine are adsorbed by the resin, and the resin regains its exchange capacity.

Quick rinsing (forward washing)-The purpose of quick rinsing (forward washing) is to remove residual salt solution in the resin layer and reduce chloride (Cl-).

Salt water re-injection-During regeneration, the salt water in the salt tank is all sucked up, so after regeneration, the water flow is controlled by the automatic control valve, and the salt tank is refilled with clean water to ensure the next regeneration.

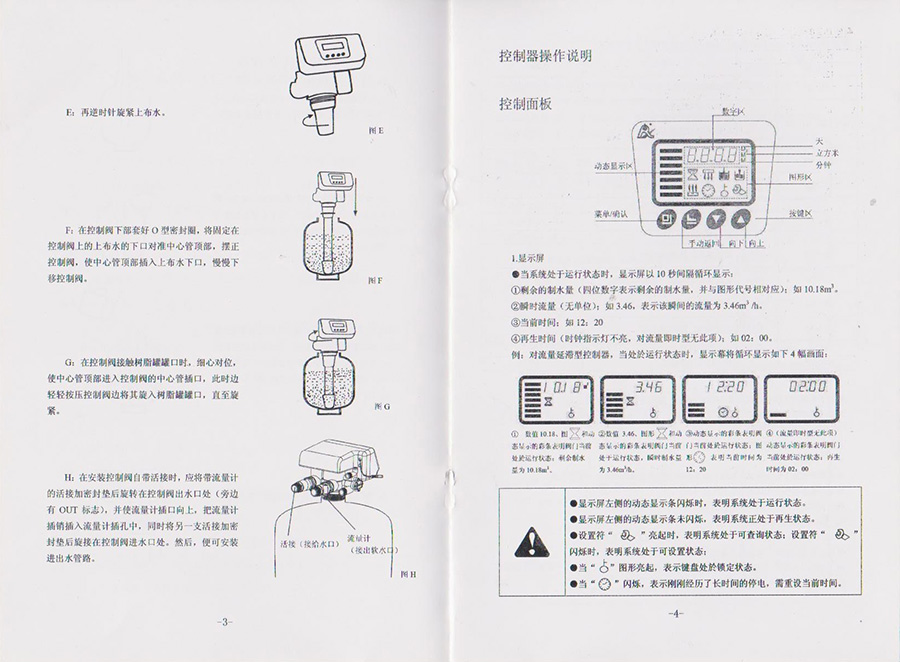

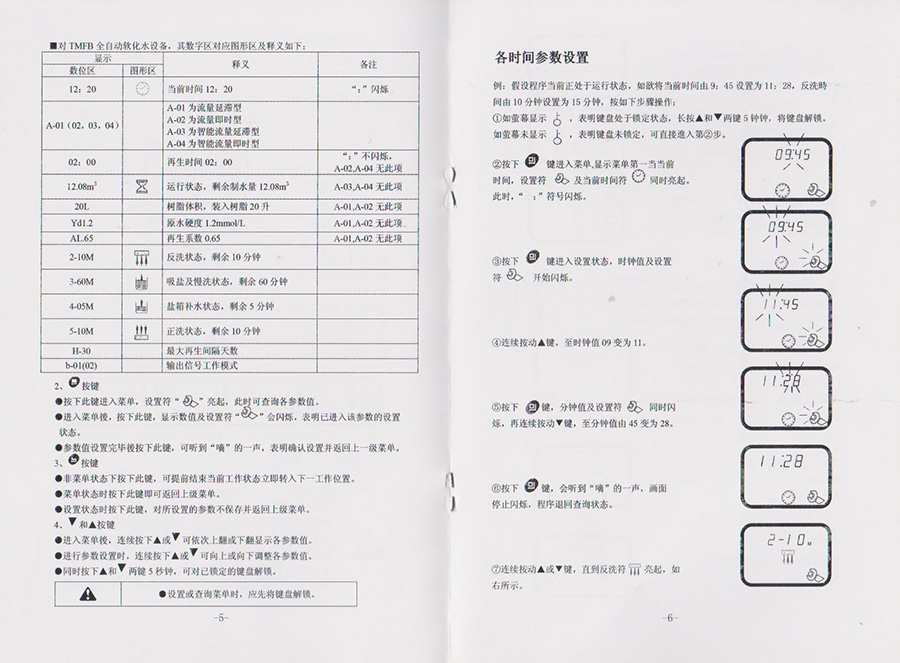

Fully automatic water softeners can be divided into time control type, flow control type, continuous water supply system type, there are single valve single tank, single valve double tank, double valve double tank parallel, large multi-valve multi tank series, etc. Combined form to meet different water needs of users. The flow type is a fully automatic regeneration of the set flow rate control, and the flow rate can be set according to the different resin loading and water quality. The time type is based on the amount of resin loading and water quality combined with the specific demand conversion time per hour, and the automatic regeneration is controlled by the set time (the regeneration cycle can be set as needed within 7 or 12 days, and the regeneration time can be arbitrarily selected within 24 hours) . The automatic soft water equipment control system technology is formed, easy to operate, reliable in operation, and microcomputer controlled, making it easier to operate and easier to manage.

(1) High degree of automation and stable operating conditions.

(2) Advanced program control device, which runs accurately and reliably, replaces manual operation, and fully realizes the automatic conversion of all aspects of water treatment.

(3) High efficiency and low energy consumption, economical operating costs. Because the overall design of the softener is reasonable, the exchange capacity of the resin can be fully exerted. The equipment uses a jet-type salt suction to replace the salt pump and reduce energy consumption.

(4) The equipment has a compact structure and a small footprint, saving capital investment, installation and commissioning, easy to use, and stable performance of running components.

3. Function:

Fully automatic water softener realizes automatic control of each step of softener operation and regeneration, and uses time, flow or other sensors to start regeneration. The basic composition of the automatic water softener is: FLECK, Autotrol or Hangzhou Runxin multi-way control valve, resin tank (including 001 × 7 resin), salt tank and piping system.

4. Basic functional characteristics:

1) High degree of automation: the automatic water softening device automatically completes the cycle of softening and regeneration according to the preset program. During the operation, it does not require any manual operation except for the periodic addition of regeneration salt, which saves a lot of manpower and material resources. Automatic controller or computer automatic controller (optional) allows users to easily adjust the operation of the system according to changes in water quality.

2) The effluent water quality is stable: the soft water device accurately sets the program according to the local water quality, and can guarantee the effluent quality under any working conditions.

3) High efficiency, low energy consumption and low operating cost: due to the reasonable overall design of the water softener and strict automatic control, the exchange capacity of the resin is guaranteed to be fully exerted, and the indicators of salt consumption and water consumption of the equipment are significantly lower than the general Compared with the softened water device, the power consumption is significantly reduced.

4) Reliable operation and long service life: the exchanger shell of the DM soft water device is made of high-strength special glass steel and composite materials, which is corrosion-resistant and aging-resistant, with an effective life of up to 50 years. The core is the only moving part. These characteristics make the control valve reliable in performance and long in service life.

5) Small footprint: advanced process design makes the water softener compact in structure and significantly reduces the footprint, saving construction investment.

6) Extremely wide use: suitable for electronic power industry, metallurgical industry, pharmaceutical industry, chemical industry, food and beverage industry, hotel and restaurant, heating station, boiler room, office building, cold storage, shopping mall, air-conditioning water, and household domestic water, etc. Water softening treatment; used for water softening treatment of various boilers such as heating, heating, and gas supply; used in domestic drinking and bathing water to reduce the hardness of raw water; used for water softening treatment of various heat exchangers such as plate and volume ; Used for chilled water treatment of air conditioners and refrigerators.

5. Special features:

▶ New automatic control

The microcomputer processor controls the equipment to automatically carry out the processes of water supply, backwashing, salt absorption, regeneration, and forward washing.

▶ Continuous and stable water supply

It can be regenerated regularly and at a constant flow rate to ensure the production of high-quality demineralized water.

▶ Reasonable and compact structure

The integrated soft water exchange tank and control valve save installation space and further improve operational reliability.

▶ Multifunctional brine system

It can automatically dissolve salt, automatically absorb salt, and automatically adjust the liquid level of the salt liquid to ensure reliable automatic regeneration.

▶ Uniform water distribution system

Can provide uniform water flow in the tank, ensure efficient use of resin, and prevent resin loss

▶ Super corrosion resistance

Avoid corrosion of equipment caused by regenerant and harsh environment

▶ Low energy consumption

Self-water consumption <2% of water production, salt consumption <100 g / mmol, electricity consumption 10W ~ 40W, power consumption is equivalent to 1% of ordinary demineralized water equipment

▶ Flexible design selection

Optional single-tank, multi-tank system, time, flow control mode; one use one standby, alternate regeneration and other operating modes.

6. Installation conditions:

There is no need for a separate equipment foundation, generally a flat cement floor, and a drainage ditch or drain should be provided within 1 meter of the equipment.

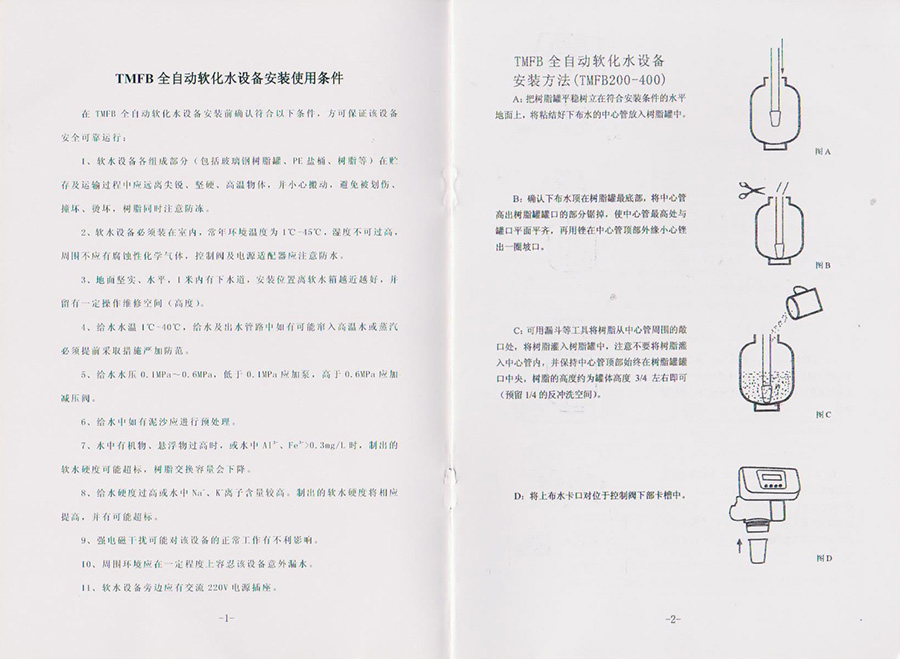

7. Installation points:

▶ The pipeline is installed with force support to prevent the control valve from being stressed.

▶ When the inlet pipe of the water softener is connected to the domestic water pipe, a backflow preventer must be installed on the inlet pipe.

▶ If the inlet water pressure is lower than 0.15MPa, pressurization measures are required.

▶ The length of the sewage pipe is less than 6m; no valve is installed on the pipe; the outlet should not be higher than the valve body and the terminal opening, so as to avoid siphoning.

▶ In addition to the water softener that uses hydraulically driven multi-way valves, a 220V power supply is required on site.

▶ Do not use iodized salt, use calcium added as a regenerant.

8. User manual of water softener:

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn