Water Treatment Equipment

Contact Us

Contact Us

产品详细

Cyclone sand remover

1. Product Introduction

This product is the second generation of our company. It integrates cyclone and filtration. Our company uses advanced technology for production. This product is mainly used to remove groundwater and solid particles in underground hot water and other water sources. It is suitable for Water source heat pump system, central air conditioning circulating cooling water, chilled water system, winter cooling and heating circulating water system, industrial cooling circulating water system, etc. It is widely used in many industrial sectors such as chemical industry, environmental protection, food, medicine, etc., and has significant effects in removing sand, turbidity, and solid-liquid separation in the field of water supply treatment.

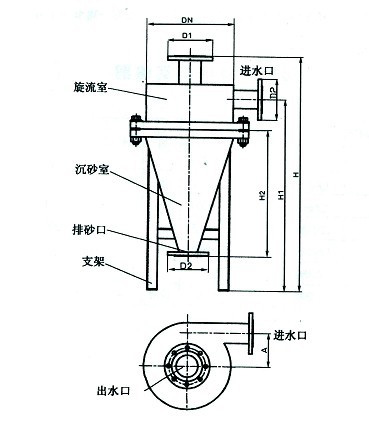

2. Working principle

The cyclone sand remover is based on the principle of screening when the solid particles in the fluid rotate in the sand remover, and then combined with filtering measures to form a new type of separation equipment. When the water flow is under a certain pressure from the sand remover After the water inlet enters the equipment in a tangential direction, there is a strong rotational movement. Due to the different density of sand and water, under the effect of centrifugal force, centripetal force, buoyancy and fluid drag, the water with low density rises and is discharged from the water outlet. The density is large The sand particles are discharged from the sewage outlet at the bottom of the equipment, and the individual tiny particles floating together along the water flow are blocked by the second-stage filtering device, so as to achieve the purpose of removing sand.

Compared with the cyclone sand remover currently on the market, a filtration unit is added (the filtration accuracy can be selected by the user), which has a high sand removal rate, saves installation space, and has a low leakage rate for individual small solids and a stable working state. advantage.

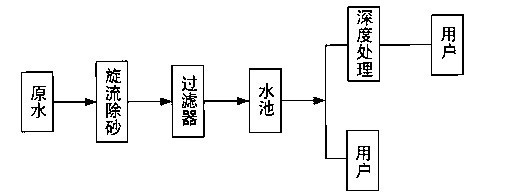

3. Process flow

Raw water-cyclone sand removal-precision filtration-storage tank-user cyclone sand remover is based on the principle of centrifugal sedimentation and density difference. When the water flow is under a certain pressure, it enters the equipment tangentially from the inlet of the sand remover. Strong rotation motion, due to the different density of sand and water, under the action of centrifugal force, centripetal buoyancy, and fluid drag force, the low-density clear water rises and is discharged from the overflow port, and the high-density sand is discharged from the bottom The sand outlet is discharged to achieve the purpose of removing sand. Under a certain range and conditions, the greater the inlet pressure of the sand remover, the higher the sand removal rate, and multiple units can be used in parallel.

4. Product Features

1) No energy consumption, fast sand removal and high efficiency.

2) Simple structure, low cost and easy installation and operation.

3) Small size, large processing capacity, saving on-site installation space.

4) Easy installation, operation and maintenance, no pollution to water, and wide application range.

5) The secondary pollution of water quality existing in other sand removal methods is avoided.

5. Selection notice

The selection of the cyclone sand remover must consider factors such as the amount of treated water, the diameter of the external pipe, the working pressure of the pipeline, the quality of the raw water and the requirements of the water quality after treatment. In general, when using a cyclone sand remover, on the premise of satisfying the flow rate, priority is given to using large-scale equipment, and it is recommended to replace several large equipment in parallel in the system in order to achieve better solid-liquid separation effect.

6. Technical parameters

1) Working temperature: normal temperature

2) Pressure loss: 0.028MPa

3) Inlet turbidity: ≤320 degrees

4) Sand removal diameter: 0.8mm

5) Water turbidity: ≤10 degrees

6) Sand removal efficiency ≥90%

7) Inlet pressure: 0.2 ~ 1.2MPa

7. Precautions for use and installation

1. The installation of the equipment should be in the form of bypass installation to meet the needs of overhauling the equipment and cleaning the filter without stopping the machine.

2. It is forbidden to turn on the device for a long time without water.

3. Equipment operation:

1) Blowdown rate: When the pressure difference between the inlet and outlet reaches 0.03-0.06MPa (or according to the pressure difference set by the system), backwash should be performed. When the water quality is poor or the new system is used for the first time, backwash for 1-2 minutes every 8 hours. After normal operation, it depends on the water quality.

2) Backwash: open the bypass valve, drain valve, close the equipment inlet valve, and backwash the filter body with water flow to clean the filter body. The backwash time depends on the water quality, generally 10-30 seconds.

3) For highly polluted systems, a short cycle high frequency backwash process should be used. When the inlet pressure is less than 0.25MPa, a backwash pump should be set up separately to increase the backwash strength and increase the amount of sewage discharged.

4) Return to working state.

A: Close the drain valve;

B: Open the inlet valve and close the bypass valve.

8. Selection Instructions

1. Equipment selection

1) Before selecting the equipment, it must be clear:

a. The nominal diameter and connection method of the pipeline connected to the water inlet and outlet of the sand remover;

b. Working pressure;

c. Swirl direction and relative position of nozzle.

2) According to the system processing flow rate or filtration accuracy, multiple "swirl flow sand removal (soil)" can be selected for series or parallel use.

3) For systems with higher accuracy requirements, the filter with higher accuracy should be installed after the “swirling sand (soil) filter according to the requirements of filtration accuracy to avoid system blockage.

2. Equipment installation

1) Installation diagram

2) The equipment can be directly placed on the ground or installed on a large foundation. The ground or foundation must be level.

3) The equipment inlet and outlet pipes and installation directions must be carried out in strict accordance with the marking on the equipment.

4) In principle, the distance of the equipment shell should not be less than 300mm.

3. Use of equipment

1) When opening the blowdown valve, apply even force to avoid artificial damage.

After the initial operation of the new system for 48 hours, open the hand hole to check and clear the debris in the machine.

ONLINE / MESSAGES

Tel:0534-2580018

E-Mail:1133231096@163.com

版权信息

CopyRight © 2020 Youxin Group ICP: 鲁ICP备18012254号-1 Powered by www.300.cn